Top 10 Best Circular Rib Knitting Machines for Quality Production

In the world of textile manufacturing, the demand for efficiency and quality has never been higher. One essential piece of equipment that meets these requirements is the circular rib knitting machine. These machines are designed to produce high-quality ribbed fabrics, which are vital in creating various garments and accessories. As the fashion industry continues to evolve, the need for advanced knitting technology has become paramount, making circular rib knitting machines a valuable asset for producers looking to enhance their output and maintain a competitive edge.

Selecting the right circular rib knitting machine can significantly impact production processes. With numerous options available on the market, understanding the features and capabilities of each machine is crucial for making informed purchasing decisions. In this article, we will explore the top 10 best circular rib knitting machines, analyzing their specifications, performance characteristics, and overall suitability for various production needs. Whether you are a small-scale operation or a large manufacturing enterprise, this guide aims to equip you with the knowledge necessary to invest in the best machinery for your knitting projects.

Understanding Circular Rib Knitting Machines and Their Importance

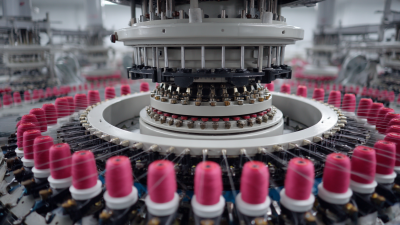

Circular rib knitting machines have become increasingly important in the textile industry, particularly for producing high-quality knitted fabrics. These machines are designed to create rib patterns, which are highly valued for their stretchability and comfort, making them ideal for items such as sweaters, leggings, and scarves. According to a report by Grand View Research, the global knitting machinery market size was valued at USD 2.30 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 4.5% through 2028. This growth is largely driven by the rising demand for knitted apparel and advancements in knitting technology.

The significance of circular rib knitting machines also lies in their ability to enhance production efficiency. By utilizing multiple needles arranged in a circular configuration, these machines can produce a continuous length of fabric, reducing the need for seams and finishing processes. A study published by TechSci Research indicated that the efficiency of circular knitting machines can improve fabric production by up to 30% compared to traditional flat knitting machines. This not only lowers production costs but also meets the increasing market demand for quick turnaround times in fashion and textile manufacturing. The integration of automation and smart technology in these machines further emphasizes their role in modern production strategies, ensuring that manufacturers keep pace with evolving consumer preferences.

Top 10 Best Circular Rib Knitting Machines for Quality Production

This bar chart represents the production speed (in meters per hour) and efficiency rating (from 1 to 10) of the top 10 circular rib knitting machines, highlighting their importance in the textile industry.

Key Features to Look for in a Quality Circular Rib Knitting Machine

When selecting a quality circular rib knitting machine, there are several key features to consider. Firstly, the machine's gauge plays a crucial role in determining the fineness of the knit. A finer gauge allows for intricate designs and softer fabrics, making it ideal for high-end garments. Additionally, a machine with adjustable tension settings is essential for achieving a consistent fabric quality, as it accommodates different yarn types and thicknesses.

Another important aspect is the machine's ease of use and setup. A user-friendly interface and clear instructions can significantly enhance productivity, especially for those who may be new to knitting technology. Furthermore, consider the machine's speed and efficiency; faster machines can help meet production demands while maintaining quality. Finally, durability should not be overlooked; well-built machines are more reliable and can withstand the rigors of continual use, ensuring a solid investment for any knitting business.

Top 10 Recommended Circular Rib Knitting Machines for Different Needs

When it comes to the textile industry, choosing the right circular rib knitting machine is crucial for optimizing production efficiency and garment quality. According to a report by The Textile Machinery Association, the demand for circular knitting machines has increased significantly, driven by the rise in knitwear popularity and the need for sustainable manufacturing practices. The right machine can help manufacturers produce high-quality ribbed fabrics that meet diverse consumer needs, from athletic wear to fashion apparel.

In selecting the best circular rib knitting machines, different factors such as machine capacity, versatility, and energy efficiency should be considered. For instance, machines that offer adjustable gauge settings provide greater flexibility in producing varied rib patterns, while energy-efficient models contribute to lower operational costs. Notably, a study by Market Research Future highlighted that the global circular knitting machine market is projected to grow at a CAGR of 5.6% from 2021 to 2027, underscoring the ongoing evolution in knitting technology and the increasing importance of investing in modern equipment.

By evaluating machines based on these criteria, businesses can enhance their production capabilities and meet the ever-changing demands of the fashion industry.

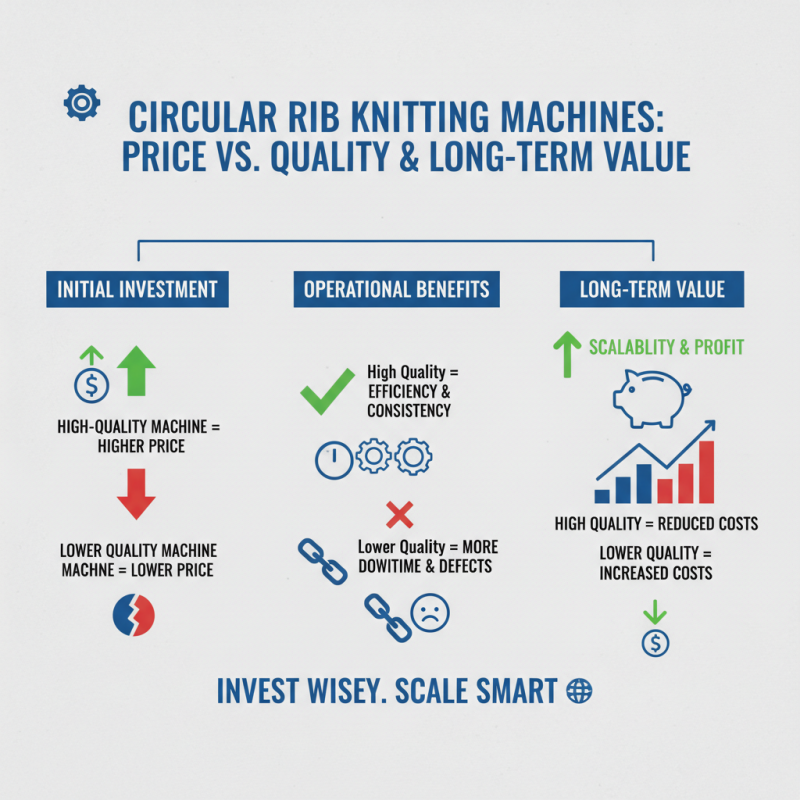

Comparative Analysis: Price vs. Quality in Circular Rib Knitting Machines

In the world of textile production, selecting the right circular rib knitting machine is crucial for achieving a balance between price and quality. Recent industry reports indicate that investing in high-quality machinery can significantly reduce long-term production costs. With manufacturers increasingly focusing on automation, knitting machines now offer greater efficiency and consistency, making them a wise investment for businesses looking to scale their operations.

When comparing different circular rib knitting machines, it’s essential to consider factors like functionality and reliability. A machine that provides adaptability allows manufacturers to produce a diverse range of fabrics while maintaining high productivity levels. For instance, advancements in technology have enabled machines to incorporate versatile settings and streamlined operations, thus optimizing the production workflow.

**Tips:**

1. When evaluating machines, assess the automation features and how they align with your production goals, ensuring you’re equipped to handle varying demands efficiently.

2. It's also advisable to analyze the total cost of ownership, considering both initial investments and ongoing operational expenses, to make a more informed decision that prioritizes quality without compromising financial viability.

Maintenance Tips for Prolonging the Life of Your Knitting Machine

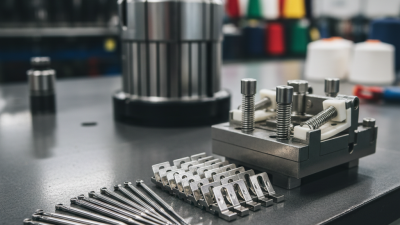

Proper maintenance of your knitting machine is crucial for ensuring its longevity and optimal performance. One key aspect of maintenance is regular cleaning. Accumulated fibers, dust, and oils can hinder the machine’s functionality. Set aside time to meticulously clean the machine after each use, paying close attention to the needle bed and any moving parts. Using a soft brush can help remove debris without causing damage. Additionally, lubricating the machine according to the manufacturer’s guidelines can significantly reduce friction and wear, contributing to smoother operation.

Another important factor in maintaining a circular rib knitting machine is checking for signs of wear and tear. Regularly inspect the needles and replace them if you notice any bending or bluntness, as this can affect the quality of your knit. Furthermore, calibrating the tension settings frequently ensures consistent results and prevents yarn breakage. Keeping the machine covered when not in use will protect it from dust and potential damage, fostering a conducive environment for its components. By following these maintenance tips, you can prolong the life of your knitting machine and enhance your production quality.

Related Posts

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today

-

2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth

-

2025 Top 10 Circular Knitting Machines to Transform Your Production Efficiency

-

10 Best Circular Knitting Machine Parts for Optimal Performance