How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

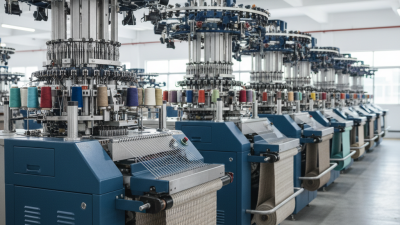

When it comes to the world of textile manufacturing, the selection of the right equipment can significantly impact your production efficiency and product quality. Among the various machines available, the circular jacquard knitting machine stands out for its versatility and ability to create intricate designs with precision. This type of machine is not only essential for producing garments but also for crafting home textiles and innovative fashion pieces. With numerous options on the market, understanding how to choose the best circular jacquard knitting machine tailored to your specific needs is crucial for ensuring optimal performance and investment return.

In this guide, we will explore the key factors to consider when selecting a circular jacquard knitting machine, from machine specifications and functionalities to the materials and types of fabrics you intend to work with. Whether you are a small workshop or a large-scale production facility, equipping yourself with the knowledge to make an informed decision will empower you to harness the full potential of this remarkable technology. Discover how the right machine can enhance your creative capabilities and boost your overall productivity in the ever-evolving textile industry.

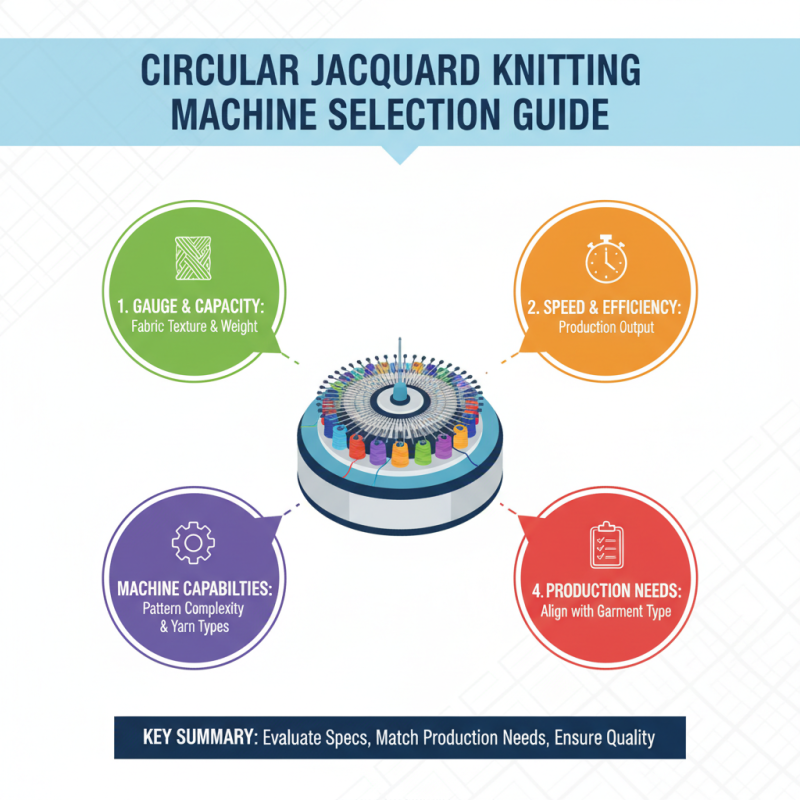

Factors to Consider When Selecting a Circular Jacquard Knitting Machine

When selecting a circular Jacquard knitting machine, several critical factors come into play to ensure that the equipment meets your specific production needs. Firstly, consider the machine's gauge, which significantly affects the fabric's texture and weight. For instance, a 7-gauge machine may be ideal for heavier knitwear, while a 16-gauge model is more suitable for lighter fabrics and finer patterns. According to a report by the Textile Machinery Association, advancements in gauge technology have led to machines capable of producing intricate designs with tighter tolerances, enhancing the overall fabric quality.

Another essential factor is the machine's production speed, often measured in stitches per minute (SPM). Modern circular Jacquard knitting machines can reach speeds of up to 1,500 SPM, which dramatically increases productivity. However, it's crucial to balance speed with the quality of the final product; high-speed machines may lead to increased wear and tear on the equipment if not properly maintained. Additionally, consider the range of patterns and designs the machine can produce, as versatility is vital in meeting diverse market demands. Research indicates that manufacturers who invest in multi-pattern capabilities see a 20% increase in order fulfillment rates, underscoring the importance of selecting a machine that can adapt to evolving fashion trends.

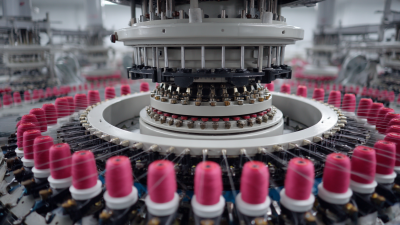

Understanding Different Types of Circular Jacquard Machines Available on the Market

When looking for the ideal circular Jacquard knitting machine, it's essential to understand the various types available on the market. One of the primary distinctions lies in the gauge, which measures the number of needles per inch. Machines with a finer gauge are suitable for producing delicate fabrics, while those with a coarser gauge can handle thicker yarns and create denser textiles. This understanding of gauge will guide you in selecting a machine that meets your specific project requirements, whether you're aiming for intricate patterns or robust designs.

Another important factor to consider is the number of feeding systems in the machine. Machines with multiple feeders allow for more complex designs by enabling the use of different yarns simultaneously. This feature is particularly beneficial for creating multi-colored patterns and textures. Additionally, these machines may offer varying levels of automation, from semi-automatic to fully computerized options, giving you flexibility based on your production needs and skill level. Understanding these types and their capabilities will empower you to make an informed decision tailored to your knitting aspirations.

Comparison of Different Types of Circular Jacquard Knitting Machines

Evaluating Machine Specifications and Capabilities for Your Production Needs

When selecting a circular jacquard knitting machine, it is crucial to thoroughly evaluate the machine specifications and capabilities to ensure they align with your production needs. Begin by considering the machine's gauge and knitting capacity. The gauge directly affects the texture and weight of the fabric produced, so it's important to choose a gauge that fits the type of garments you aim to create. Additionally, check the machine's production speed and efficiency, as these factors will dictate how quickly you can meet manufacturing demands without compromising quality.

Another essential aspect to consider is the versatility of the machine. Look for features that allow for a range of stitch patterns and fabric designs, which can enhance your product line and cater to diverse customer preferences. Pay attention to the software integration capabilities, as modern machines often come equipped with advanced technology that enables designers to create intricate patterns efficiently. Evaluating the technical support and ease of maintenance offered with the machine will also greatly influence the long-term productivity and reliability of your operations. By dissecting these specifications and capabilities, you can confidently choose a circular jacquard knitting machine that best suits your production requirements.

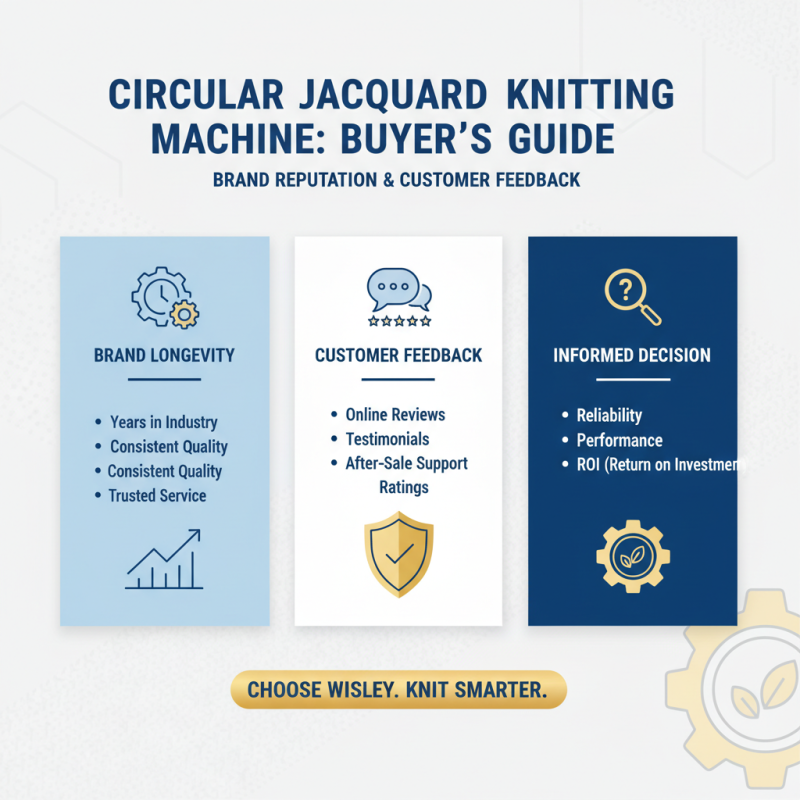

Assessing Brand Reputation and Customer Feedback in the Knitting Industry

When choosing the best circular jacquard knitting machine for your needs, assessing brand reputation and customer feedback is crucial in making an informed decision. The knitting industry is rife with options, and understanding how a brand is perceived can provide insights into their reliability and performance. Look for brands that have been in the industry for a significant amount of time; longevity often correlates with consistent quality and trusted service.

Customer feedback serves as a valuable resource for potential buyers. Reading reviews and testimonials can reveal not only the strengths and weaknesses of specific machines but also the customer's overall satisfaction. Pay attention to patterns in the feedback—if multiple users cite similar issues or praises, it's a strong indicator of the machine's true capabilities. Additionally, engaging in knitting communities and forums can provide firsthand experiences from other knitters, giving you a clearer perspective.

**Tips:**

1. Check online reviews on reputable knitting blogs and forums to get diverse opinions on different machines.

2. Don't hesitate to reach out to current users of the machines you're considering to ask about their experiences and recommendations.

3. Look for brands that offer good customer support and warranties, as this indicates confidence in their product and can save you from future headaches.

Analyzing Cost-Effectiveness and Return on Investment for Your Purchase

When considering the purchase of a circular jacquard knitting machine, understanding its cost-effectiveness and potential return on investment (ROI) is crucial. These machines can vary significantly in price, with features that cater to different production needs. Evaluating the initial costs against your projected output and the quality of the finished products is essential in determining whether the investment is justified. Take into account factors such as production speed, material costs, and potential for customization, as these will directly affect your profitability.

Tips: Before making a purchase, conduct thorough market research to compare prices and features of different machines. Look for equipment with energy-efficient technology, as this can lead to lower operational costs over time. Additionally, consider the long-term benefits of investing in a machine that offers scalability; as your business grows, the ability to adapt your production line can lead to increased profits.

Ultimately, focus on how the knitting machine will enhance your production capabilities and contribute to your business goals. Assess the machine’s durability and maintenance requirements; machines that require less frequent servicing can save you money and minimize downtime. By carefully analyzing these aspects, you can ensure that your investment will pay off in the long run, enhancing both your operational efficiency and bottom line.

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

| Feature | Description | Cost ($) | Expected Lifespan (Years) | Estimated Annual Return ($) | ROI (%) |

|---|---|---|---|---|---|

| Number of Needles | Varies from 20 to 60 | 8000 | 10 | 1200 | 15% |

| Speed (RPM) | Up to 100 RPM | 9500 | 10 | 1400 | 15% |

| Fabric Types Supported | Various yarns including cotton and wool | 7000 | 12 | 1600 | 23% |

| Ease of Use | User-friendly interface with touchscreen | 6500 | 8 | 1400 | 22% |

| Warranty Period | 2 years standard warranty | 6000 | 7 | 1000 | 17% |

Related Posts

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

Top 10 Best Circular Rib Knitting Machines for Quality Production

-

How to Choose the Best Circular Rib Knitting Machine for Your Needs

-

2025 Top 10 Circular Knitting Machines to Transform Your Production Efficiency

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today

-

Top 10 Essential Machines and Parts Every Manufacturer Should Know