How to Choose the Best Circular Rib Knitting Machine for Your Needs

When it comes to selecting the best circular rib knitting machine for your specific needs, the decision can often feel overwhelming. With numerous options available and varying features, it’s essential to consider both functionality and your unique production requirements. According to knitting expert Dr. Emily Carter, "A well-chosen circular rib knitting machine can significantly enhance both the quality of your products and the efficiency of your workflow." This highlights the importance of understanding the characteristics that make a circular rib knitting machine a perfect fit for your projects.

The intricate nature of rib knitting demands machines that not only meet production goals but also offer versatility and ease of use. As you navigate through the myriad of choices, keep in mind the factors such as gauge, yarn compatibility, and the types of rib structures you wish to create. Emphasizing the right features can lead to better craftsmanship and ultimately elevate your knitting experience. By carefully evaluating these aspects, you can ensure that your investment in a circular rib knitting machine will yield positive results in both productivity and quality.

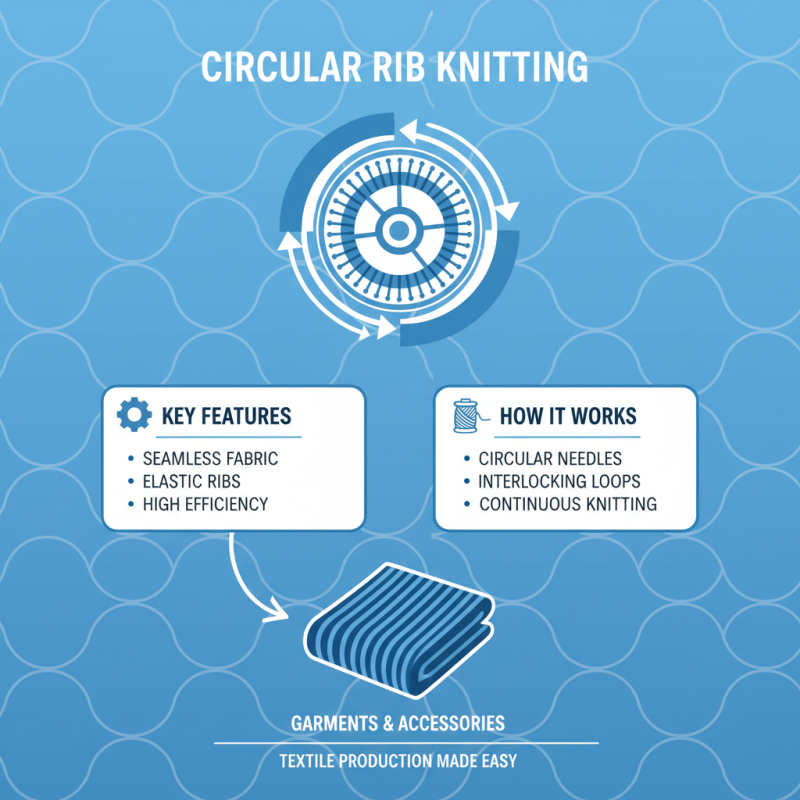

Understanding Circular Rib Knitting Machines: An Overview

Circular rib knitting machines are specialized tools designed for creating ribbed fabrics, which are commonly used in various textile products, including garments and accessories. These machines work by using a series of needles arranged in a circular format, allowing for continuous knitting without seams. Understanding their functionality is essential for anyone looking to incorporate ribbed patterns into their knitting projects, as these machines can significantly enhance efficiency and production quality.

When selecting a circular rib knitting machine, it's important to consider several factors. The gauge of the machine determines the fineness or thickness of the knitted fabric, which directly affects the type of garments that can be produced. Additionally, the feeding system plays a crucial role in how yarn is delivered to the needles, impacting the overall speed and consistency of the output. Knowledge of the machine's capabilities, such as the variety of stitches it can perform and the range of yarns compatible with it, will ultimately guide users in choosing a model that best suits their specific needs and production goals.

Key Features to Consider When Selecting a Circular Rib Knitting Machine

When selecting a circular rib knitting machine, it's essential to consider key features that align with your specific needs. One of the most crucial aspects is the machine's gauge, which determines the thickness of the yarn you can use. A variety of gauges allows for more flexibility in your projects, enabling you to experiment with different yarn weights and textures. Additionally, consider the number of needles the machine possesses; more needles can increase your production capabilities and result in finer, more intricate designs.

Another important feature is the machine's ease of use. Look for machines that offer user-friendly controls, which can simplify the setup and operation process. Features like automatic tension adjustment and electronic pattern programming can significantly enhance your knitting experience. Moreover, durability is key; a robust machine will ensure longevity, even with regular use.

Tips: Always assess the machine's compatibility with the type of garments you aim to produce. If you're focusing on high-volume production, opt for a machine known for its speed and efficiency. Lastly, reading reviews and seeking recommendations from experienced knitters can provide invaluable insights into the most reliable options available.

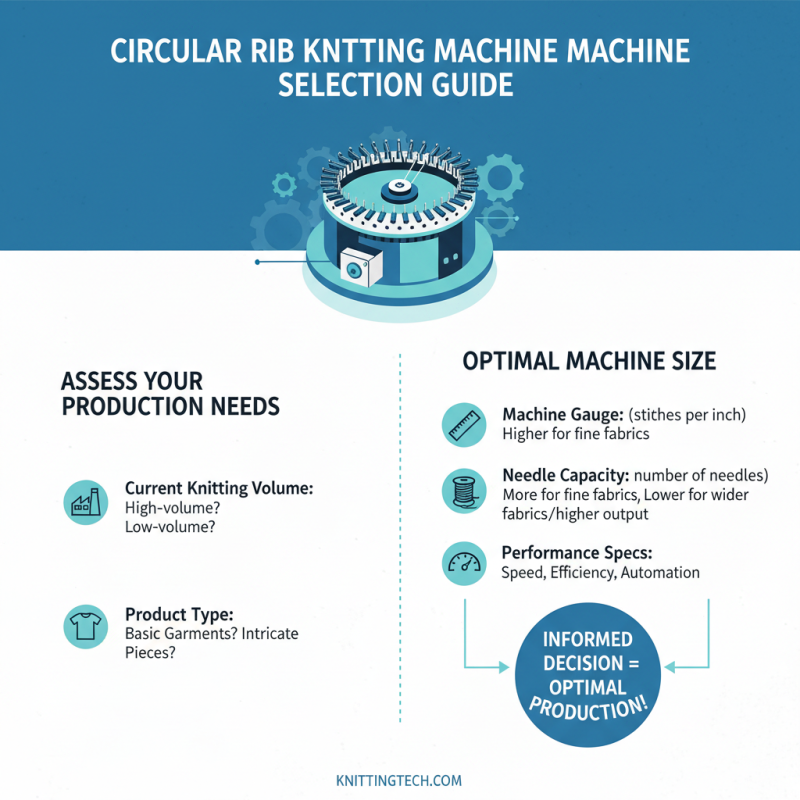

Assessing Your Production Needs for Optimal Machine Sizing

When selecting a circular rib knitting machine, assessing your production needs is crucial to determine the optimal machine size. Start by evaluating your current knitting volume and the types of products you plan to produce. Are you focusing on high-volume production of basic garments or creating more specialized, intricate pieces? Your answer will guide your decision on the machine's gauge, needle capacity, and overall performance specifications.

Tips: Always consider the future growth of your production. Opt for a machine that can handle an increase in demand or diversifying product lines without necessitating immediate replacement. Additionally, think about the machine's versatility; a machine capable of producing a variety of ribbed fabrics will serve your needs better in fluctuating markets.

Another factor to consider is space and layout in your production area. A larger machine may require additional floor space and infrastructure, including power supply and maintenance access. Be realistic about your operational environment; fitting a machine into a cramped space could lead to inefficiencies. Ensure the chosen machine aligns seamlessly with your existing setup for optimal productivity and workflow.

Comparing Different Brands: Quality, Reliability, and Price

When choosing the best circular rib knitting machine, a critical factor to consider is the comparison of different brands based on quality, reliability, and price. Quality is paramount; it encompasses the materials used in construction, the precision of the knitting mechanisms, and the machine's ability to produce consistent and flawless rib patterns. Higher-quality machines often come with advanced technology that enhances the knitting process, allowing for greater creativity and flexibility in design. Therefore, it’s essential to assess user reviews and expert recommendations regarding the durability and performance of various brands.

Reliability is another key aspect that can significantly impact your knitting experience. A reliable machine will not only perform well over time but also require minimal maintenance and repairs. Investigating the warranty options and customer support services offered by different brands can provide insight into their commitment to reliability. Lastly, price is a crucial consideration; while it can be tempting to opt for the most affordable option, it's important to weigh the cost against the features offered. Investing in a slightly more expensive machine may yield better long-term value, provided it meets your specific knitting needs. Balancing these factors will help you make an informed decision on the best circular rib knitting machine for your projects.

Comparison of Circular Rib Knitting Machines

Maintenance and Support: Ensuring Long-Term Performance of Your Machine

When investing in a circular rib knitting machine, focusing on maintenance and support is crucial for ensuring long-term performance. Regular upkeep not only prolongs the lifespan of the machine but also enhances its efficiency. According to industry reports, machines that undergo systematic maintenance can have up to a 30% increase in productivity compared to those that are neglected. This underscores the importance of routine check-ups and servicing procedures.

One essential tip for maintaining your knitting machine is to establish a comprehensive maintenance schedule. Regular lubrication, tension adjustments, and cleaning can prevent common issues such as yarn breakage and inconsistent stitching. Additionally, connecting with a reliable support provider can ensure you have access to necessary parts and technical assistance when needed. Industry professionals recommend keeping a log of all maintenance activities to help identify patterns that might indicate underlying problems before they escalate.

Furthermore, invest time in understanding the documentation that comes with your machine, such as user manuals and maintenance guides. These resources often include troubleshooting tips and best practices tailored to your particular model. By fostering an environment of proactive care and utilizing available resources, you can significantly enhance the reliability and performance of your circular rib knitting machine over time.

How to Choose the Best Circular Rib Knitting Machine for Your Needs - Maintenance and Support: Ensuring Long-Term Performance of Your Machine

| Feature | Importance | Maintenance Frequency | Expected Lifespan | Support Available |

|---|---|---|---|---|

| Automatic Tension Control | High | Weekly | 10+ years | 24/7 Online Support |

| Digital Patterning System | Medium | Monthly | 8-10 years | Email Support and Training |

| Variable Speed Control | High | Bi-weekly | 12+ years | Phone Support |

| Ease of Threading | Medium | As Needed | 10+ years | In-person Training Available |

| User-Friendly Interface | High | Quarterly | 15+ years | Comprehensive User Manual |

Related Posts

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

Top 10 Best Circular Rib Knitting Machines for Quality Production

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

Top 5 Best Used Knitting Machines for Quality and Affordability

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today

-

10 Best Circular Knitting Machine Parts for Optimal Performance