2025 How to Choose the Right Knitting Machine Parts for Your Projects

In the evolving landscape of the textile industry, selecting the appropriate knitting machine parts is pivotal for optimizing production and achieving high-quality outcomes. According to a recent report from the International Textile Manufacturers Federation, the global knitting machinery market is anticipated to grow at a CAGR of 4.5% from 2023 to 2027, underlining the increasing significance of advanced machinery components. With myriad options available, understanding the specific requirements of each project has never been more critical.

Expert in the field, Dr. James L. Mitchell, a renowned textile engineer, emphasizes the importance of informed decision-making when it comes to "knitting machine parts." He states, "The right components not only enhance efficiency but also ensure the longevity of the machine, allowing producers to stay competitive in a rapidly changing market." As knitters and manufacturers alike navigate this complex terrain, comprehending the essential functions and compatibility of various parts becomes essential for maximizing both productivity and creativity in knitting projects.

In the forthcoming sections, we will delve deeper into the key considerations for selecting knitting machine parts tailored to specific project needs, enabling enthusiasts and professionals to make educated choices that align with their creative visions and operational goals.

Understanding Different Types of Knitting Machine Parts Available

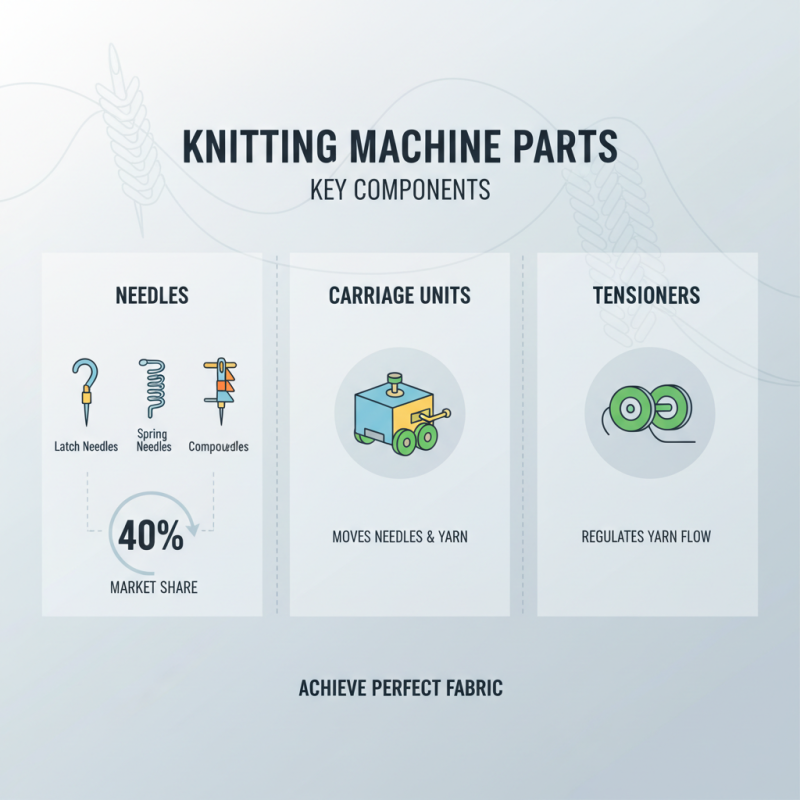

When selecting the right knitting machine parts for your projects, it’s essential to understand the various types available. Generally, knitting machine components can be divided into categories such as needles, carriage units, and tensioners. Needles come in different types, including latch, spring, and compound needles, each serving unique functions depending on the yarn and project type. According to industry reports, the needle segment accounts for approximately 40% of the total knitting machine parts market, highlighting their importance in achieving specific fabric textures and patterns.

Tensioners also play a crucial role in knitting, as they regulate the tightness or looseness of the yarn during the stitching process. Proper tension ensures consistent stitch quality, which is vital for both aesthetic appearance and structure. The choice of tensioners can affect the overall output, with an estimated 25% of knitters citing tension-related issues as a common problem in their projects.

**Tips:** When choosing parts, consider the materials you’ll be working with and the desired outcome. Research compatibility with your machine to avoid functional issues. Additionally, it’s worthwhile to invest in high-quality components, as they significantly enhance your knitting experience and can lead to more professional results. Always consult with knowledgeable suppliers or sewing professionals to make informed decisions for your specific projects.

Identifying the Specific Needs of Your Knitting Projects

When embarking on a knitting project, understanding the specific needs of your endeavor is crucial to selecting the right knitting machine parts. Each project may have different requirements depending on the type of yarn, stitch, and design you want to implement. For instance, delicate lace projects often necessitate finer needles and a more precise tension control, whereas heavier or textured yarns may benefit from sturdier parts that can handle greater bulk. Evaluating the materials and complexity of your project will help determine the essential components you need for optimal results.

Furthermore, considering the scope of your project can guide you in choosing parts that enhance your efficiency. If you anticipate working on large items, such as sweaters or blankets, investing in a machine with extended bed lengths and robust feeding mechanisms can significantly reduce your processing time. Alternatively, for small, intricate works, you might prioritize accessories that facilitate detail work, like specialized presser feet or tension disks. Analyzing both the scale and intricacy of your projects ensures that every part you select not only aligns with your creative vision but also supports seamless execution.

2025 How to Choose the Right Knitting Machine Parts for Your Projects - Identifying the Specific Needs of Your Knitting Projects

| Part Type | Specific Function | Material | Compatibility | Recommended Projects |

|---|---|---|---|---|

| Needles | Create stitches | Steel or Plastic | Most machines | Sweaters, Scarves |

| Carriage | Holds needles, controls tension | Plastic | Specific brands | Sweaters, Blankets |

| Thread Tension Dial | Adjusts thread tension | Metal | Most machines | Any knitting project |

| Sinker | Controls stitch formation | Metal | Specific machines | Complex patterns |

| Weight System | Maintains tension | Various | Varies by model | Large projects |

Evaluating Quality and Compatibility of Knitting Machine Components

When selecting parts for your knitting machine, evaluating the quality and compatibility of components is paramount to ensuring a smooth and successful crafting experience. Quality parts not only enhance the performance of your machine but also extend its lifespan, allowing for continuous creativity without interruptions. Look for components made from durable materials that can withstand the rigors of repetitive use. Checking for certifications or reviews can also provide insights into the reliability and reputation of the parts you are considering.

Compatibility is another crucial aspect to consider. Not all knitting machine components work interchangeably, so it's essential to ensure that the parts you choose fit your specific model and meet the requirements of your projects. Research the specifications of your knitting machine and compare them to the parts you are interested in.

**Tips:**

- Always refer to your machine's manual for recommended specifications and compatibility details.

- If possible, consult online forums or communities of fellow knitters to gather first-hand experiences regarding the compatibility of certain parts with different projects.

- When in doubt, contacting the manufacturer for guidance can prevent costly mistakes and ensure you select the right components for your knitting endeavors.

2025 Knitting Machine Parts Quality and Compatibility Evaluation

Budgeting for Knitting Machine Parts: Cost Considerations

When budgeting for knitting machine parts, it's essential to consider both the initial costs and the long-term investment involved. Prices can vary significantly based on the quality and functionality of the parts. Basic components, such as needles and tension disks, are often more affordable, making them a suitable starting point for beginners or those working on smaller projects. However, investing in higher-quality parts can enhance the performance and durability of your machine, leading to better results over time.

Additionally, it's wise to factor in the costs associated with maintenance and potential upgrades. Regular upkeep of your knitting machine can prevent costly repairs and prolong its lifespan. Moreover, as you advance in your knitting skills or expand your project scope, you may find the need for specialized parts that can accommodate your new design ideas. Setting aside a budget for these upgrades can ultimately save you money and frustration in the long run, allowing for a smoother knitting experience and more satisfying creative outcomes.

Tips for Maintenance and Upgrades of Knitting Machine Parts

When it comes to ensuring the longevity and performance of your knitting machine, regular maintenance and timely upgrades are essential. One of the first tips for maintaining your knitting machine parts is to keep everything clean and lubricated. Dust and lint can accumulate quickly, leading to inefficient functioning and potential damage. Regularly clearing out these materials, along with applying appropriate lubricants to the moving parts, can greatly enhance the machine’s performance and extend its lifespan.

Upgrading certain components can also make a significant difference in the quality of your knitting projects. Consider investing in higher-quality needles or tension rods, as these can improve stitch consistency and reduce the likelihood of breakage. Additionally, staying informed about new technologies and compatible attachments can help you find parts that elevate your craft. Regularly checking and upgrading electrical components, such as motors and sensors, ensures that your machine operates smoothly and efficiently, allowing you to focus on your creative endeavors without interruptions.

Related Posts

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

Top 5 Best Used Knitting Machines for Quality and Affordability

-

Top 10 Best Circular Rib Knitting Machines for Quality Production