How to Choose the Right Machine Parts for Your Equipment Needs

When it comes to maintaining and operating machinery, the selection of the right machine machine parts is crucial for efficiency and longevity. According to industry expert John Thompson, a leading authority in mechanical engineering, "Choosing the right machine parts can dramatically influence the performance and reliability of your equipment." This statement emphasizes the importance of making informed decisions in the realm of machine machine parts, whether for repairs or upgrades.

In the ever-evolving landscape of technology and machinery, the need to understand which parts suit your specific equipment requirements becomes more vital than ever. Various factors, such as compatibility, quality, and supplier reputation, play a pivotal role in your decision-making process. From bearings to motors, each component must be carefully selected to ensure optimal performance. By delving into the nuances of these elements, operators can enhance their workflows, minimize downtime, and ultimately achieve greater productivity.

As we explore the ins and outs of selecting the ideal machine machine parts, we will discuss practical tips, common pitfalls to avoid, and insights that will empower you to make better choices for your equipment needs. Whether you are an experienced professional or a newcomer in the field, understanding how to navigate this landscape will serve you well in maintaining a successful operation.

Understanding Your Equipment's Specific Requirements

Understanding the specific requirements of your equipment is crucial for selecting the right machine parts. Every piece of machinery is designed with particular tolerances, load capacities, and operational characteristics that necessitate compatible parts.

According to a report by the Global Machinery Parts Association, nearly 30% of equipment failures stem from the use of incompatible components. This statistic highlights the importance of analyzing your equipment’s specifications thoroughly before making a decision.

When assessing your equipment's needs, consider factors such as size, weight, material, and intended application. For instance, heavy-duty machinery in high-load operations often requires parts made from high-strength alloys to withstand wear and prevent failures. A study conducted by the American Society of Mechanical Engineers indicates that using parts manufactured from appropriate materials can improve operational efficiency by 20% and reduce maintenance costs by 15%. By meticulously examining these specifications and aligning them with your operations, you can ensure optimal performance and longevity of your machinery.

Identifying Compatible Machine Parts and Specifications

Choosing the correct machine parts for your equipment is crucial for maintaining efficiency and performance. To ensure compatibility, it’s essential to understand the specifications of both the existing equipment and the parts being considered. According to industry reports, over 30% of machinery failures can be traced back to inadequate part compatibility or substandard components. This highlights the necessity of thorough research when identifying parts.

When evaluating machine parts, consider factors such as material quality, dimensions, and performance ratings. Always refer to the equipment manual for the manufacturer’s specifications. Importantly, leverage resources like technical datasheets and compatibility databases which are increasingly available in the industry today. These tools can help clarify what will fit best in your given application, thus minimizing the risk of machine downtime.

Tips: Always keep a record of existing machinery specifications and any modifications made over time. This document will serve as a critical reference when sourcing parts, ensuring you look for the correct sizes and materials that will not only fit but also enhance operational efficiency. Additionally, discussing your requirements with experienced technicians can provide insights into potential upgrades or alternative options that align with your goals.

Machine Parts Selection Criteria

Evaluating Quality Standards and Manufacturer Reputation

When selecting machine parts for your equipment, evaluating quality standards and the reputation of manufacturers is crucial. Quality standards are vital indicators of a part’s durability, performance, and reliability. These standards often encompass metrics such as material specifications, dimensional tolerances, and performance testing protocols. By ensuring that the parts meet or exceed industry quality standards, you can substantially reduce the risk of equipment failure, which can lead to costly downtimes and repairs.

In addition to quality standards, the reputation of the manufacturer plays a significant role in the decision-making process. Researching the manufacturer’s history, customer reviews, and industry certifications can provide insight into their commitment to quality and customer service. A reputable manufacturer is likely to have a proven track record of producing reliable parts and addressing customer issues effectively. Engaging with suppliers who prioritize transparency and quality can forge long-lasting partnerships, ensuring that you receive the best parts for your specific equipment needs.

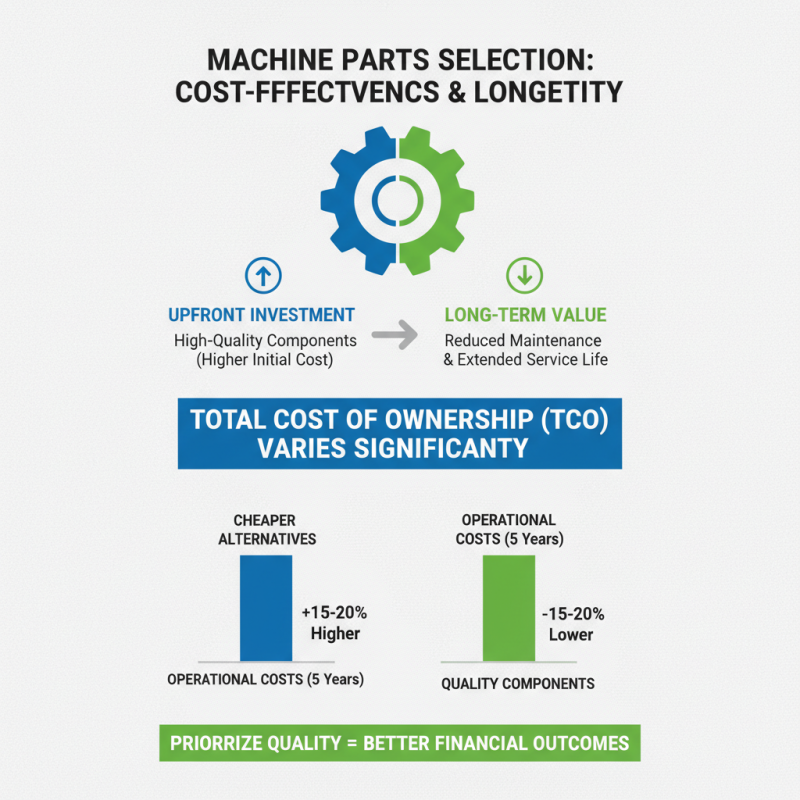

Assessing Cost-Effectiveness and Longevity of Parts

When selecting machine parts, assessing their cost-effectiveness and longevity is crucial for ensuring optimal performance and sustainability. According to recent industry reports, such as those from the Machinery and Equipment Institute, the total cost of ownership (TCO) can vary significantly depending on the choice of parts. For instance, opting for high-quality components may require a higher upfront investment but can lead to reduced maintenance costs and longer service life, ultimately resulting in better financial outcomes. Data indicates that companies that prioritize quality experience an average of 15-20% lower operational costs over a five-year period compared to those that opt for cheaper alternatives.

Furthermore, longevity should not be overlooked, as it directly impacts productivity and downtime. Statistics from the Equipment Efficiency Group reveal that equipment with high-durability parts can operate up to 30% longer before requiring replacements. The average downtime for machinery due to part failures can lead to losses of approximately $22,000 per hour in manufacturing environments. By investing in durable parts, organizations not only enhance their operational efficiency but also contribute to a more sustainable industrial ecosystem by reducing waste and the frequency of replacements. Thus, while evaluating machine parts, a strategic focus on cost-effectiveness and longevity can significantly bolster overall equipment efficiency and profitability.

Exploring Customization Options and Aftermarket Solutions

When selecting machine parts for your equipment, exploring customization options and aftermarket solutions can significantly enhance performance and longevity. Customization allows you to specify parts that meet the unique demands of your machinery, ensuring compatibility and efficiency. For instance, you can opt for tailored materials that withstand specific environmental conditions or design specifications that align with your operational needs. By prioritizing customization in your machine parts selection, you can optimize functionality and reduce the risk of operational disruptions.

Tips: Always assess the compatibility of customized parts with existing equipment to avoid complications. Consult with experts in the field who can guide you in choosing materials and designs that align with your operational goals.

Aftermarket solutions also play a crucial role in maintaining and upgrading your equipment. Utilizing aftermarket parts can provide cost-effective alternatives without compromising quality. They often come with enhancements not found in original parts, offering improved durability and performance. However, it’s essential to ensure that these aftermarket options comply with safety and regulatory standards.

Tips: Research reputable suppliers and read customer reviews to ensure the quality of aftermarket parts. Consider warranty and return policies when making your purchase to safeguard your investment.

How to Choose the Right Machine Parts for Your Equipment Needs - Exploring Customization Options and Aftermarket Solutions

| Part Category | Customization Options | Aftermarket Solutions | Estimated Cost | Lead Time |

|---|---|---|---|---|

| Gearbox | Custom ratios and sizes | Replacement gear sets | $1,500 - $3,000 | 2-6 weeks |

| Hydraulic Pump | Flow rate adjustments | Refurbished pumps | $800 - $2,000 | 1-4 weeks |

| bearings | Size and material options | Aftermarket high-performance bearings | $50 - $300 | 1-2 weeks |

| Conveyor Belts | Length and thickness customization | Reinforced belts | $100 - $500 | 1-3 weeks |

Related Posts

-

2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today

-

Top 5 Best Used Knitting Machines for Quality and Affordability

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

Top 10 Best Circular Rib Knitting Machines for Quality Production

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business