How to Choose the Right Machine and Parts for Your Industrial Needs

In the ever-evolving industrial landscape, selecting the right machine and parts is paramount for operational efficiency and productivity. According to a report by the International Federation of Robotics, global sales of industrial robots reached over 400,000 units in 2020, showcasing a growing reliance on advanced machinery in various sectors. This trend underscores the importance of making informed choices when it comes to procuring machines and components that meet specific industry requirements.

Expert in industrial machinery, Dr. James Morton, emphasizes the critical nature of this decision-making process, stating, "The effectiveness of industrial operations hinges on the optimal selection of machine and parts tailored to both current needs and future growth.” As businesses strive to enhance performance and minimize downtime, understanding the nuances of various machines and their corresponding parts becomes essential. Carefully evaluating specifications, compatibility, and the latest technological advancements will lead organizations toward sustainable growth and competitive advantage in the market.

Identifying Your Industrial Requirements and Specifications

When selecting the right machine and parts for industrial needs, the first step is to thoroughly identify the specific requirements and specifications that must be met. According to a report by the International Society of Automation, approximately 70% of industrial automation failures can be traced back to poor initial requirement specification. Therefore, a clear understanding of the operational environment, production goals, and desired output quality is imperative. Businesses should conduct a comprehensive analysis of their processes, evaluating factors such as load capacity, cycle time, and compatibility with existing systems.

Moreover, it is essential to consider the longevity and durability of the machines and components. Research published by the National Institute of Standards and Technology highlights that equipment reliability directly impacts overall productivity and maintenance costs. For instance, machines designed for high-stress operations must be sourced with materials that can withstand intense conditions without compromising performance. Industry benchmarks suggest that an organization can save up to 30% on maintenance costs by investing in reliable machinery from the onset, thus affirming that thorough specification assessment and thoughtful selection are critical for achieving optimal operational efficiency.

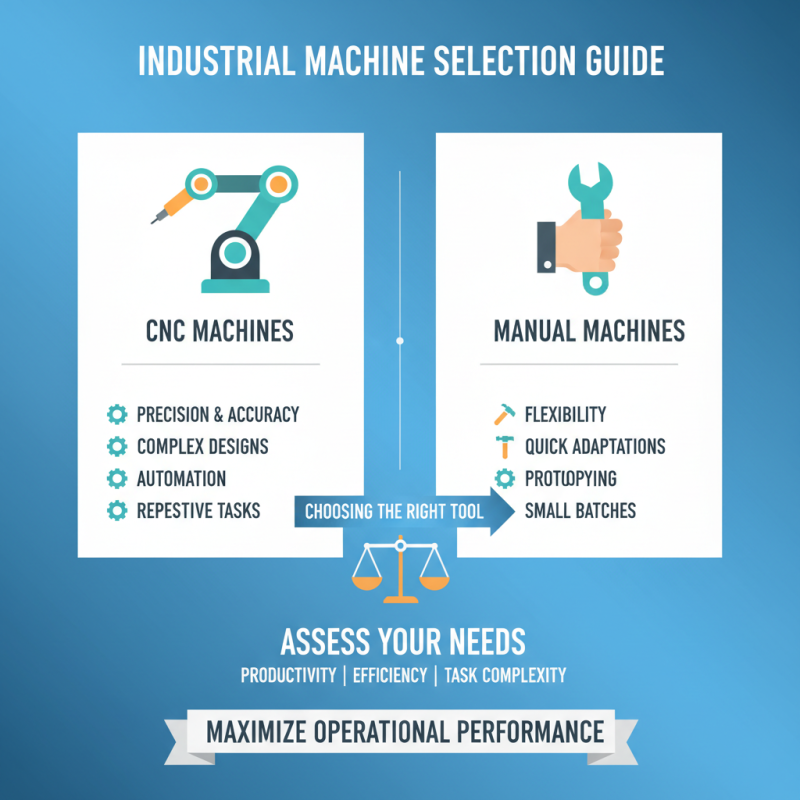

Assessing the Benefits of Different Machine Types

When selecting the right machine for industrial needs, it is crucial to assess the benefits of different types of machines available. Each machine type serves specific functions and offers unique advantages that can significantly impact productivity and operational efficiency. For instance, CNC machines are known for their precision and ability to handle complex designs, making them ideal for tasks that require high levels of accuracy. On the other hand, manual machines may be beneficial in settings where flexibility and quick adaptations to changing tasks are necessary.

Another important consideration is the adaptability of the machine to different production environments. Some machines are designed to operate effectively in various conditions, whether in high-volume production lines or smaller workshops. Additionally, the maintenance requirements and operational costs of each machine should also be evaluated. Machines that require less frequent maintenance can save time and resources over the long term, enhancing overall productivity. Ultimately, understanding the specific benefits of each type of machine allows businesses to make informed decisions that align with their operational needs and long-term goals.

Evaluating Quality and Reliability of Machine Parts

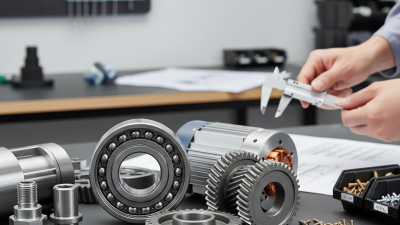

When selecting machine parts for industrial applications, evaluating quality and reliability is crucial for ensuring optimal performance and longevity. Quality can be assessed through material selection, manufacturing processes, and adherence to industry standards. High-quality materials, such as durable alloys or composites, often translate to enhanced resistance against wear and tear, thus prolonging the lifespan of the machine. Additionally, manufacturers that follow rigorous quality control protocols tend to produce parts that meet precise specifications and minimize operation disruptions.

Reliability, on the other hand, is associated with the consistency of machine parts during operation. It can be evaluated through factors such as the part's design, its history of performance in similar applications, and the availability of warranties or guarantees from the manufacturer. Components that have been rigorously tested for performance under various operating conditions often inspire greater confidence in their reliability. Moreover, understanding the support services provided by the manufacturer, such as maintenance guidelines and availability of replacement parts, plays a significant role in choosing parts that contribute to a seamless and efficient industrial process.

How to Choose the Right Machine and Parts for Your Industrial Needs - Evaluating Quality and Reliability of Machine Parts

| Part Type | Material | Durability Rating | Weight (kg) | Price ($) | Lead Time (days) |

|---|---|---|---|---|---|

| Gear | Steel | High | 2.5 | 50 | 10 |

| Bearing | Ceramic | Medium | 1.2 | 75 | 5 |

| Drive Belt | Rubber | Low | 0.5 | 15 | 7 |

| Hydraulic Cylinder | Aluminum | High | 7.5 | 200 | 14 |

| Control Valve | Brass | Medium | 3.0 | 120 | 12 |

Understanding Maintenance and Support Services Available

When selecting machines and parts for industrial applications, it's essential to consider not only the equipment itself but also the maintenance and support services that accompany them. Maintenance is crucial to ensuring the longevity and reliability of industrial machines. A well-structured maintenance program can mitigate unexpected downtimes, enhance performance, and ultimately save costs. When choosing equipment, inquire about the maintenance services offered, including routine inspections, parts replacement, and access to expert technicians. Understanding these offerings can help you determine if they align with the specific operational needs of your facility.

In addition to preventive maintenance, support services play a vital role in the operational efficiency of industrial equipment. Evaluate the availability of technical support after the purchase of machines and parts, as this can significantly impact productivity. Determine if the support services include 24/7 assistance, training for operators, and resources for troubleshooting. A reliable support system can ensure that your team is well-equipped to handle any technical challenges that may arise, thereby maintaining optimal workflow and safety standards in your operations.

Comparing Costs and Budget Considerations for Machinery Investments

When investing in industrial machinery, a thorough cost comparison is essential to ensure that the chosen equipment aligns with your operational budget and financial goals. First, it's important to evaluate both the initial purchase price and the long-term operational costs. This includes considering not only the upfront expenditure but also maintenance, energy consumption, and potential downtime costs associated with older or less reliable machines. By factoring in these elements, businesses can have a clearer picture of the total cost of ownership, allowing for more informed decision-making.

Budget considerations also play a critical role in selecting the right machine and parts. Companies should assess their current financial situation and anticipated growth to determine a feasible investment range. Cost-effective machinery may offer lower prices but could compromise productivity or reliability if not suited to specific tasks. Therefore, it's vital to balance budget constraints with the necessity for high-quality equipment that meets industry standards. A well-researched budget plan not only ensures that the investment is manageable but also that it supports the company's long-term operational efficiency and growth potential.

Cost Comparison of Industrial Machinery

This bar chart illustrates the estimated costs of various types of industrial machinery to aid in budget considerations for machinery investments.

Related Posts

-

2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth

-

How to Choose the Right Machine Parts for Your Equipment Needs

-

How to Choose the Best Circular Rib Knitting Machine for Your Needs

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today

-

Top 5 Best Used Knitting Machines for Quality and Affordability