How to Choose the Best Rib Knitting Machine for Your Projects

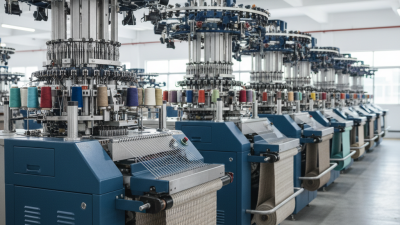

When it comes to knitting projects, selecting the right equipment can make all the difference in the final outcome. One such essential tool for knitters is the rib knitting machine, designed specifically to create versatile ribbed patterns that add both texture and stretch to garments. As the popularity of ribbed designs continues to rise in the fashion world, understanding how to choose the best rib knitting machine becomes paramount for both novice and experienced knitters alike.

In this guide, we will explore key factors to consider when selecting a rib knitting machine that suits your specific needs. From the machine’s capabilities and ease of use to the types of yarn it accommodates, every detail plays a significant role in enhancing your knitting experience. By the end of this discussion, you will be equipped with the knowledge necessary to make an informed decision, ensuring that your projects not only achieve the desired aesthetic but also showcase the quality and craftsmanship that comes from using the right rib knitting machine.

Understanding Rib Knitting Machines: Types and Features

Rib knitting machines come in various types, each featuring unique capabilities suited for different projects. The most common types are flatbed and circular knitting machines. Flatbed machines excel in producing intricate patterns and are ideal for garments requiring detailed ribbed designs. In contrast, circular knitting machines are perfect for creating seamless tubes, making them a popular choice for items like socks and hats. According to a report by the Knitting Industry Association, the demand for flatbed machines has surged due to their versatility, reflecting a 15% increase in sales over the past three years, indicating a trend towards custom and fitted apparel.

When selecting a rib knitting machine, it’s crucial to consider features that enhance usability and output quality. Look for machines with adjustable tension settings, as these allow for greater control over the fabric’s elasticity and overall look. Additionally, advanced models often come equipped with automatic yarn feeders and intuitive programming interfaces, streamlining the knitting process. Industry experts highlight that machines featuring these advanced capabilities can improve production efficiency by up to 30%, making them a worthwhile investment for both hobbyists and professionals seeking to maximize their creative potential. The choice between manual and automated systems will largely depend on your specific production needs and the complexity of the designs you intend to create.

Key Factors to Consider When Choosing a Rib Knitting Machine

When selecting a rib knitting machine, several key factors can significantly influence the success of your projects. First and foremost is the machine's gauge, which determines the thickness of the yarn you can use and the fineness or coarseness of the ribs produced. A finer gauge, typically ranging between 3-8 mm, is suitable for delicate fabrics, while a coarser gauge (10-14 mm) is ideal for making thicker knitwear. According to a recent industry report, knits made with appropriate gauge can increase fabric resilience by up to 30%, maximizing durability and enhancing overall wearability.

Another vital consideration is the machine's capability for multi-functionality. Machines that offer a range of stitch types and settings can enable users to experiment with various designs, which can be a great advantage for creative projects. The current trend in the knitting industry highlights that over 60% of knitters prefer versatile machines that allow them to explore different fabric textures. By investing in a machine with adaptability, crafters can expand their creative repertoire and potentially increase their productivity by 20%.

Tip: Before making a purchase, it's beneficial to evaluate your specific project needs, including the types of yarn and fabric you intend to work with. Additionally, consider the machine's maintenance requirements, as ease of upkeep can greatly affect long-term satisfaction. Opt for machines with user-friendly features and robust customer support for a smoother knitting experience.

How to Choose the Best Rib Knitting Machine for Your Projects - Key Factors to Consider When Choosing a Rib Knitting Machine

| Feature | Importance | Recommendation |

|---|---|---|

| Machine Type | High | Consider either a manual or electronic machine, depending on your experience level. |

| Gauge | Medium | Choose a gauge that matches the yarn thickness you plan to use. |

| Ease of Use | High | Look for user-friendly interfaces and clear instructions. |

| Price | Medium | Set a budget and balance quality with cost. |

| Brand Reputation | High | Research reviews and recommendations from other knitters. |

| Warranty and Support | Medium | Ensure there is a good warranty and customer support. |

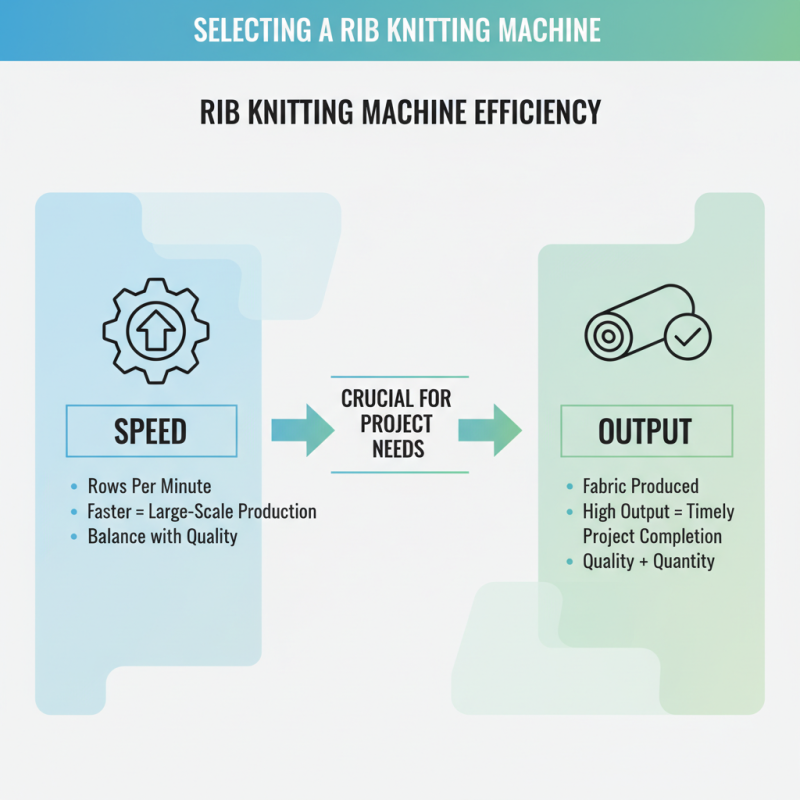

Efficiency Ratings: Speed and Output in Rib Knitting

When selecting a rib knitting machine, understanding efficiency ratings—specifically speed and output—becomes crucial in meeting your project needs. A machine's speed, typically measured in rows per minute, indicates how quickly it can produce knit fabric. Higher speeds are advantageous for large-scale production, allowing you to complete projects in a fraction of the time compared to slower machines. However, it's essential to balance speed with the quality of the finished product, as faster doesn't always guarantee better craftsmanship.

Output capacity directly correlates with productivity. This metric refers to the volume of fabric that can be produced within a certain timeframe and is influenced by both the machine's design and the type of yarn used. Machines that offer flexibility in yarn thickness and stitch patterns can significantly enhance output. Moreover, consider features like automated functions that streamline the knitting process, further boosting efficiency. A well-chosen rib knitting machine should not only align with your production speed requirements but also ensure that the final outcome meets your design aspirations, combining efficiency with creativity.

Comparative Analysis of Popular Rib Knitting Machine Brands

When selecting a rib knitting machine for your projects, it's essential to conduct a comparative analysis of the most popular brands in the market. According to the Knitting Industry Report 2023, the demand for rib knitting machines has surged by 25% over the last two years, driven by the growing popularity of sustainable fashion and customized knitwear. The analysis reveals that while some brands excel in speed and efficiency, others offer advanced features that cater to specific knitting needs, making the choice highly dependent on individual project requirements.

For instance, one can consider factors such as stitch versatility, ease of use, and maintenance requirements. Recent data indicates that machines with a greater range of stitch patterns can significantly reduce production time, a crucial factor for high-volume knitwear production. Furthermore, durability is a critical aspect, with reports suggesting that models made with heavy-duty materials tend to have longer lifespans and fewer breakdowns—an important consideration for any serious knitter. An understanding of these variables not only aids in selecting the right machine but also ensures that the investment leads to higher quality output and efficiency in rib knitting projects.

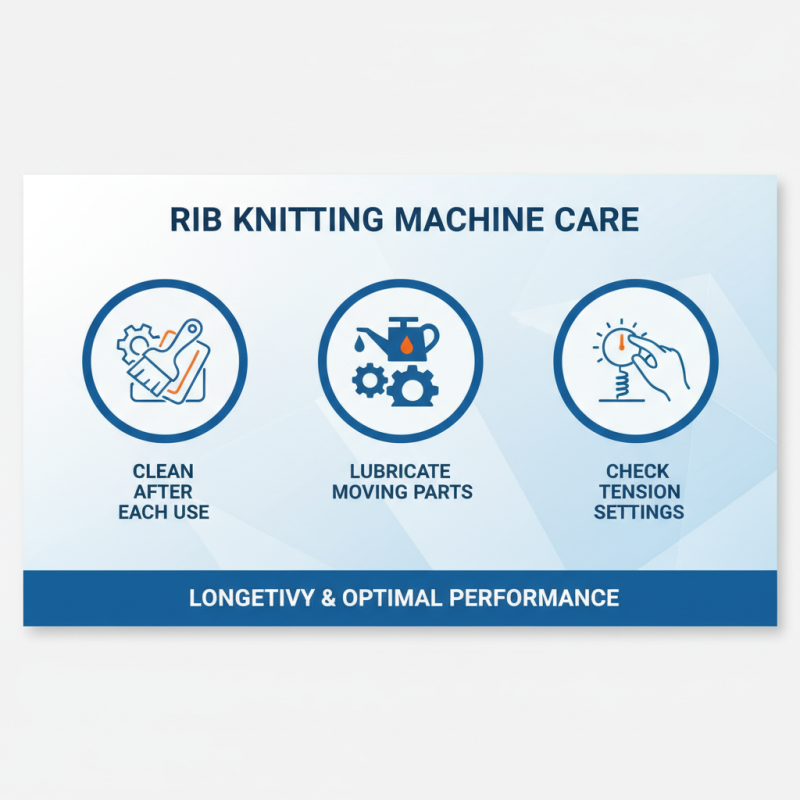

Maintenance and Support: Ensuring Longevity for Your Machine

Maintaining your rib knitting machine is crucial for ensuring its longevity and optimal performance throughout your projects. Regular maintenance routines should include cleaning the machine after each use, checking for any debris or dust that may have built up, and ensuring all moving parts are lubricated appropriately. By doing so, you prevent the accumulation of grime that can lead to more significant issues over time. Additionally, pay attention to the machine's tension settings, as improper tension can affect your knitting quality and may cause mechanical strain.

Support for your knitting machine plays a pivotal role in its longevity as well. Familiarize yourself with the warranty and support services available to you, as reputable manufacturers often provide helpful resources such as manuals, troubleshooting guides, and customer service options. Participate in online communities or local knitting groups to tap into a wealth of shared knowledge regarding machine care and best practices. Engaging with fellow knitters can also help you discover tips on extending the life of your machine, ensuring it remains a reliable tool in your crafting arsenal for years to come.

Related Posts

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

-

2025 How to Choose the Right Knitting Machine Parts for Your Projects

-

How to Choose the Right Machine Parts for Your Equipment Needs

-

Top 10 Jersey Knitting Machines for Efficient and Quality Production

-

Top 10 Best Circular Rib Knitting Machines for Quality Production