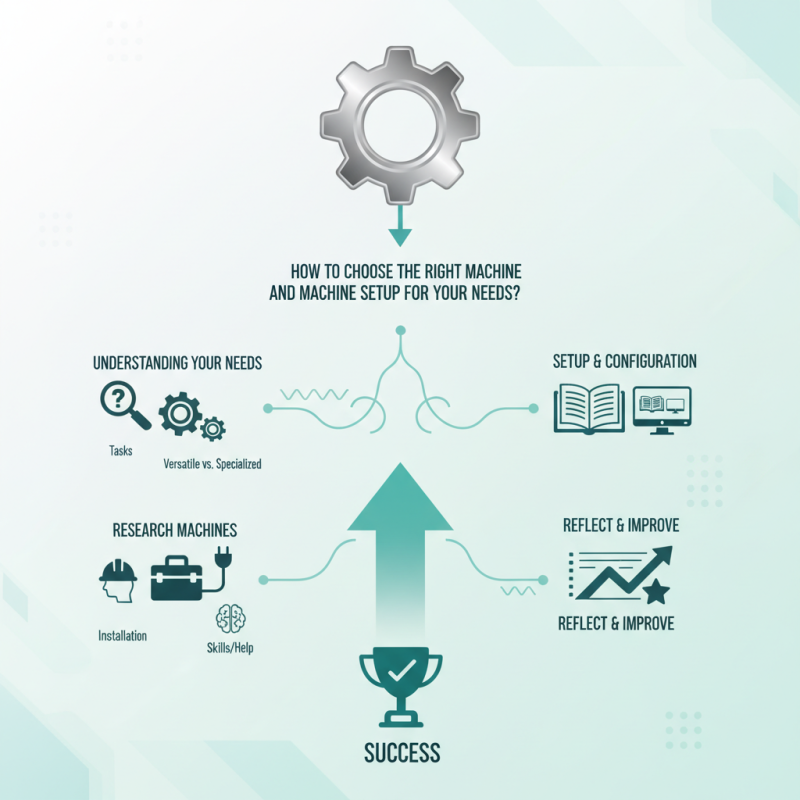

How to Choose the Right Machine and Machine Setup for Your Needs?

Choosing the right machine and machine setup is crucial for any project. The right tools can make a significant difference. They can enhance productivity and ensure quality results.

Understanding your needs is the first step. Consider the tasks you will perform. Then, research different types of machines. Do you need a versatile machine or a specialized one? Each option has its advantages. However, you may face challenges in selecting the perfect fit.

Setup is just as important as the machine itself. Proper installation and configuration impact performance. Small mistakes can lead to inefficiencies. Evaluate your skills or seek help if necessary. Reflect on your past experiences; they can guide your decision-making. The right machine and machine setup can drive success, but it takes effort to get there.

Identifying Your Specific Needs: Assessing Machine Requirements

Choosing the right machine can be daunting. It starts with understanding your specific needs. Are you looking for speed, precision, or durability? Each factor plays a crucial role in your decision. Assessing your requirements will help narrow down choices.

Tips: Make a list of must-have features. This list can guide your search. Consider the environment where the machine will be used. Will it face heavy dust, moisture, or extreme temperatures? These factors can greatly affect performance.

Don’t forget about future needs. Sometimes, we focus on the present and overlook upcoming demands. A machine that meets today’s goals may not suffice tomorrow. Think about expansion or changes in your projects. Flexibility is key for long-term satisfaction.

Tips: Keep a journal of machine performance over time. Note what works and what does not. Reflecting on these observations helps improve decision-making in the future.

Understanding Different Machine Types: Key Features and Functions

When selecting the right machine, understanding various types is essential. Each machine serves different functions. For instance, CNC machines excel in precise cutting, while lathes are great for shaping materials. Their key features often determine suitability for your specific tasks.

Tips: Consider the material you will work with. Some machines work better with metals, while others suit wood or plastics.

Often, users overlook ease of use. Complex machines might offer advanced functions but can cause frustration. A straightforward setup can save you time and effort. Ensure that the machine you choose includes user-friendly controls and support documentation.

Lastly, think about space requirements. Some machines are compact, while others need ample room. If your workspace is limited, a smaller machine might be a wiser decision. Don't settle without exploring all options. Research, reflect, and find the best fit for your needs.

Machine Types and Their Key Features

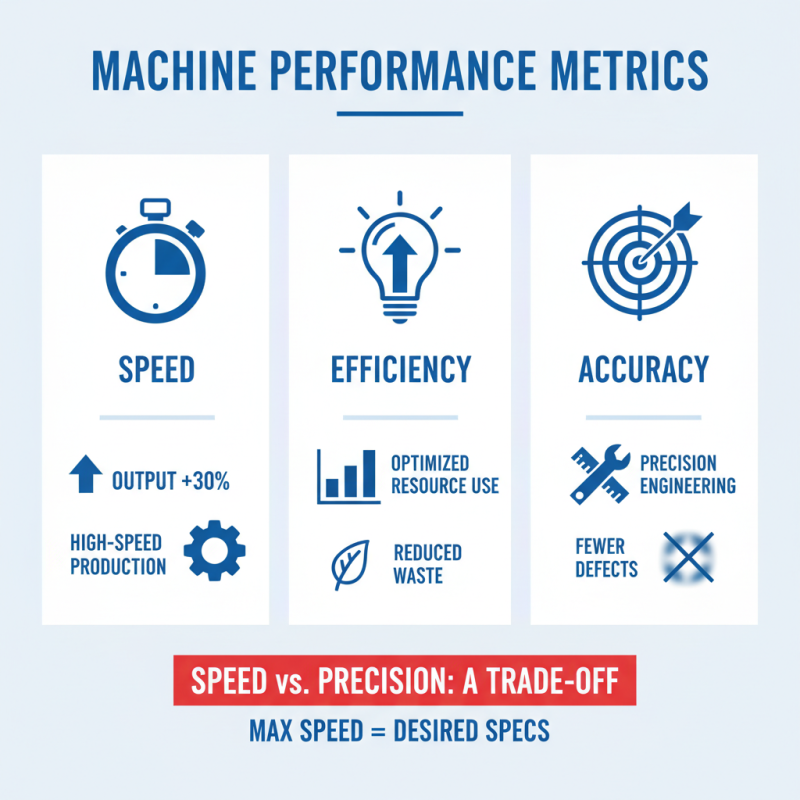

Evaluating Machine Performance Metrics: Speed, Efficiency, and Accuracy

When selecting a machine, evaluating performance metrics is crucial. Speed, efficiency, and accuracy often define a machine's capability. For instance, recent industry reports indicate that production lines with high-speed machines can increase output by up to 30%. However, faster speeds can compromise precision. A machine running at maximum speed may not always hit the desired specifications.

Efficiency is another essential metric. Combining speed with energy savings is key. According to the latest studies, machines that optimize energy consumption can reduce operational costs by up to 25%. Yet, energy-efficient designs might require longer setup times, causing delays. Companies must weigh these trade-offs.

Accuracy is paramount in manufacturing. Machines that maintain a high degree of precision can ensure quality products. Some data suggests that reducing error rates to below 2% can significantly improve customer satisfaction. However, achieving such accuracy may involve higher initial investments or advanced technology, which some businesses might overlook. Balancing these factors often leads to challenging decisions that require careful consideration.

Analyzing Cost-Benefit Factors: Initial Investment vs. Long-Term Savings

Analyzing cost-benefit factors is crucial when selecting the right machine for your needs. Initial investment is often significant. This upfront cost can be daunting. However, low-quality machines may lead to more expenses later. When faced with a choice, it's essential to think beyond the purchase price.

Consider the long-term savings a machine might offer. High-efficiency machines can lead to reduced operational costs. For example, machines that consume less energy can lower monthly bills. While these machines may cost more upfront, they can pay off over time. Similarly, reliable machines often require fewer repairs, saving additional money.

Reflect on your usage patterns. A machine that fits your immediate need might not be ideal in the long run. Over time, your production needs could change. Think about possible expansions or shifts in demand. What seems a good deal now may not be suitable later. Balancing initial costs and future savings is key to making a wise decision.

Ensuring Proper Setup: Installation, Calibration, and Maintenance Considerations

Proper installation is crucial for any machine. A poor setup can lead to inefficiencies. Take the time to read the manual thoroughly. Each machine comes with specific requirements. Ignoring them may cause damage or incorrect functioning. Ensure the machine is placed on a stable surface. This prevents vibrations that could affect performance.

Calibration is another key aspect. It ensures that the machine operates accurately. Follow the calibration steps as outlined in the manual. Sometimes, adjustments may be necessary after initial use. Don’t assume it’s perfect after the first setup. Regular checks will help maintain its precision.

Maintenance is often overlooked but is vital for longevity. Schedule routine inspections to catch potential issues early. Lubrication and cleaning should not be neglected. It’s easy to forget these small tasks. However, they make a big difference. Create a maintenance log to keep track of services performed. Small missteps in setup or care can lead to larger problems later.

How to Choose the Right Machine and Machine Setup for Your Needs?

| Aspect | Considerations | Example Specifications |

|---|---|---|

| Machine Type | Evaluate based on required output and production volume. | CNC Lathe, 3D Printer, Injection Molder |

| Installation | Ensure proper location with adequate space and infrastructure. | Access to power, ventilation, and safety protocols |

| Calibration | Regular checks to ensure precision and maintain quality. | Use of calibration tools, standard measurement protocols |

| Maintenance | Scheduled maintenance to prevent breakdowns and prolong life. | Daily checks, monthly servicing, annual overhauls |

| Training | Skill development for operators to ensure safe and efficient use. | Operator manuals, hands-on training sessions |

Related Posts

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

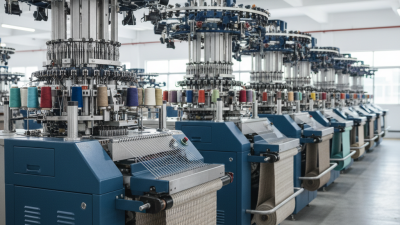

Top 10 Best Circular Rib Knitting Machines for Quality Production

-

How to Choose the Best Rib Knitting Machine for Your Projects

-

What is a Sarkular Machine and How Does it Work?

-

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

-

Top 10 Tips for Buying Cheap Knitting Machines That Save You Money