Top 10 Essential Knitting Machine Parts You Need to Know About

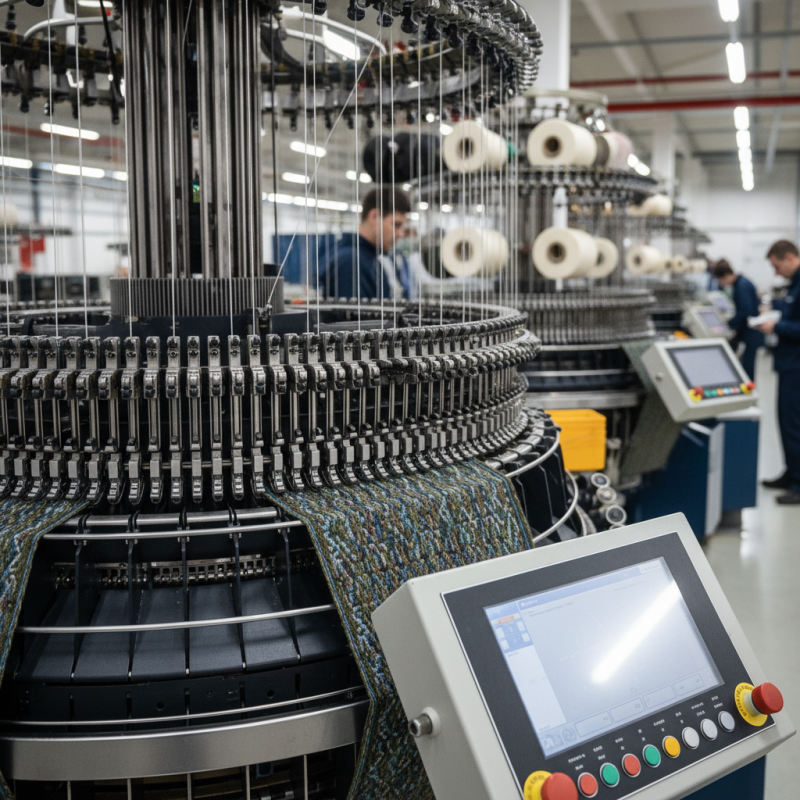

As the demand for high-quality knitwear continues to rise, understanding the essential components of knitting machines has become increasingly crucial for manufacturers and artisans alike. According to the Knitting Industry Report 2023, efficient knitting machine parts can enhance production efficiency by up to 35%, leading to significant cost savings and improved product quality. Experts like Dr. Emily Chen, a prominent figure in textile engineering, emphasize the importance of these components, stating, "The efficiency and functionality of knitting machines are directly tied to the quality of their parts; investing in superior knitting machine parts is fundamental for any producer aiming to excel in today’s competitive market."

In the world of textile production, each part of a knitting machine plays a vital role in the overall manufacturing process. From the needles and sinkers to the yarn tensioners and electronic controls, the proper functioning of these components determines not only the speed of production but also the intricacy of the designs that can be achieved. The 2023 State of Knitting Technology report indicates that innovations in knitting machine parts have paved the way for more complex patterns and textures, appealing to a broader range of consumers. Therefore, understanding and investing in the right knitting machine parts is essential for anyone looking to thrive in this dynamic industry.

Essential Components of a Knitting Machine: An Overview

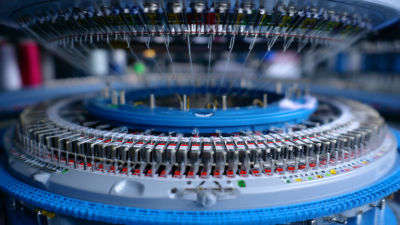

Knitting machines are intricate devices composed of several essential components that work together to create fabric efficiently. Understanding these parts is crucial for anyone looking to optimize their knitting experience. At the heart of any knitting machine is the needle bed, which holds the needles that carry out the knitting process. These needles move up and down to create stitches, while the yarn feeder supplies the necessary yarn. A properly functioning needle bed ensures consistent tension and even fabric production.

Another critical component is the carriage, which moves across the needle bed, guiding the yarn and forming stitches. It is equipped with various mechanisms that allow for different stitch patterns. The tension plate is equally important; it regulates the yarn's tension as it feeds into the needles, affecting stitch quality. Additionally, the sinker plate helps maintain the position of the stitches during the knitting process, preventing them from loosening or shifting. Knowing these essential components allows knitters to troubleshoot issues effectively and enhances their overall productivity on the machine.

Top 10 Essential Knitting Machine Parts You Need to Know About

This chart illustrates the key components of a knitting machine, showcasing their significance in the overall functionality.

Understanding the Functionality of the Knitting Machine Needle

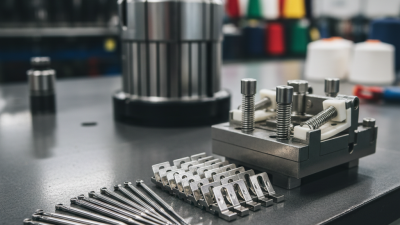

The knitting machine needle is a crucial component that directly impacts the quality and efficiency of the knitting process. Designed to pierce through the yarn and create stitches, the needle has a variety of designs tailored for different knitting techniques and materials. Traditionally, needles come in different gauges to accommodate various yarn weights, enabling knitters to achieve a range of fabric textures. Understanding the specific functions of different types of needles, such as latch needles for latch hook knitting or spring needles for more elastic designs, can transform the ease and end result of projects.

Furthermore, the proper alignment and maintenance of the knitting machine needle significantly influence the overall functioning of the machine. A misplaced or dull needle can lead to dropped stitches, uneven tension, and even damage to the yarn. Regularly inspecting the needle for wear and ensuring it is securely in place can help prevent such issues and ensure a smooth knitting experience. Knitters should also become familiar with needle replacement procedures and the compatibility of different needles with their respective knitting machines to maintain optimal performance and achieve their desired knitting outcomes.

The Role of the Yarn Guide in Successful Knitting Operations

The yarn guide plays a crucial role in successful knitting operations, serving as the navigator that directs the yarn seamlessly through the knitting machine. Its primary function is to maintain optimal tension and alignment of the yarn as it feeds into the needles. This ensures a consistent stitch formation, which is vital for achieving both structural integrity and aesthetic quality in the finished product. Without a properly functioning yarn guide, issues such as tangling, uneven tension, or even breakage can occur, disrupting the entire knitting process.

Moreover, the yarn guide contributes to the overall efficiency of the knitting operation. By allowing the yarn to flow smoothly, it minimizes the chances of machine jams and reduces downtime, which can significantly enhance productivity. Different designs of yarn guides can accommodate various types of yarn, from delicate fibers to thicker strands, making it a versatile component in any knitting machine setup. Ultimately, understanding the importance of the yarn guide not only helps in troubleshooting problems but also empowers knitters to achieve their desired outcomes with precision and professionalism.

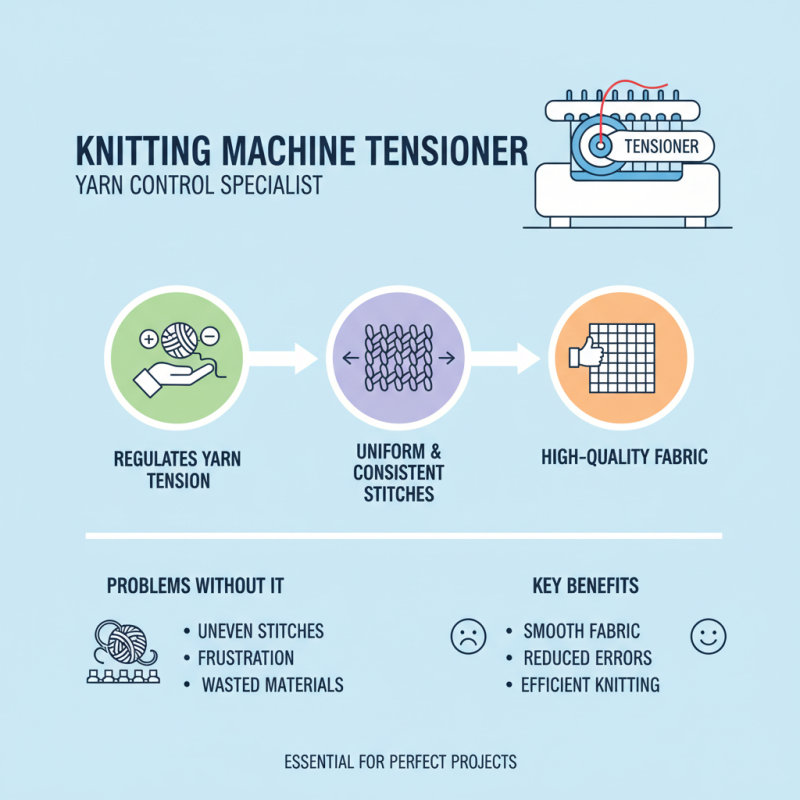

Examining the Importance of the Tensioner in Yarn Control

The tensioner is a critical component of any knitting machine, playing an essential role in yarn control. It regulates the amount of tension applied to the yarn as it feeds through the machine, ensuring that stitches are uniform and consistent. Without proper tension, your finished project can suffer from uneven stitches, causing frustration and wasted materials. This part ensures that the yarn does not get too loose or too tight, which is vital for achieving the desired fabric quality.

When working with a knitting machine, understanding how to adjust and maintain your tensioner can greatly enhance your knitting experience. Here are some tips: Regularly check the tension settings before starting a new project to ensure optimal performance. Experiment with different tension levels when working with various yarn types; for instance, thicker yarns often require different settings compared to finer yarns. Additionally, keep an eye on the tensioner for any signs of wear or damage, as this can impact its effectiveness and lead to uneven tension.

Fine-tuning the tensioner may take some practice, but mastering this essential part will lead to more professional-looking results. If you're encountering issues such as missed stitches or yarn breakage, reevaluate your tension settings and make adjustments as necessary. A well-maintained tensioner is your ally in the quest for beautifully crafted knitwear.

Key Features of the Carriage: Efficiency in Knitting Production

The carriage is a pivotal component of any knitting machine, playing a crucial role in enhancing the efficiency of knitting production. This part is responsible for moving the yarn across the needles, ensuring that the required tension is maintained during the knitting process. A well-functioning carriage will not only speed up production time but also improve the quality of the finished fabric.

When operating your knitting machine, it's essential to keep the carriage clean and well-lubricated to prevent rust and deterioration. A clean carriage glides smoothly along its track, which translates to fewer interruptions and a more consistent output. Additionally, regularly checking for any wear and tear can help in identifying issues before they escalate into costly repairs.

For optimal performance, explore the various stitch settings available on your machine's carriage. Understanding how different stitch types affect your fabric can open up new creative possibilities. If you're working on intricate designs, don't hesitate to use the built-in features of your carriage to help simplify complex patterns. Adapting your technique to maximize the carriage’s capabilities will lead to impressive results and a more enjoyable knitting experience.

Top 10 Essential Knitting Machine Parts You Need to Know About - Key Features of the Carriage: Efficiency in Knitting Production

| Part Name | Key Features | Functionality | Material |

|---|---|---|---|

| Carriage | Efficient yarn handling, smooth movement | Controls the knitting process by moving back and forth | Aluminum or high-strength plastic |

| Needles | Variety of sizes and types for different yarns | Holds and transfers yarn to create stitches | Steel or nylon |

| Sinkers | Support yarn and help form stitches | Prevents loops from unraveling | Steel or composite materials |

| Cam System | Adjusts needle height and movement | Enables complex stitch patterns | Durable steel |

| Yarn Feeders | Ensures consistent yarn supply | Prevents yarn breakage | Plastic or metal |

| Tension Plates | Controls yarn tension during knitting | Ensures proper stitch formation | Metal or engineered plastic |

| Take-up Roller | Maintains the fabric's length | Rolls up finished fabric | Plastic or rubber |

| Knitting Bed | Surface where stitches are formed | Supports all knitting operations | Cast iron or aluminum |

| Selector System | Allows selection of different stitches | Enables stitch pattern variety | Steel or hard plastic |

| Control Panel | User interface for machine operations | Controls speed, tension, and patterns | Plastic with electronic components |

Conclusion

Understanding the key knitting machine parts is essential for anyone looking to optimize their knitting experience. This article delves into the critical components of a knitting machine, starting with the functionality of the knitting machine needle, which plays a vital role in creating stitches. The yarn guide is another important part, ensuring the smooth delivery of yarn during operations. Additionally, the tensioner is crucial for maintaining the right tension, preventing yarn breakage and ensuring uniform results.

The carriage is highlighted for its features that enhance knitting efficiency, making production faster and more streamlined. Lastly, practical maintenance tips are provided to help prolong the lifespan of these knitting machine parts, ensuring they operate effectively over time. By focusing on these essential elements, knitters can improve both their skills and the longevity of their machines.

Related Posts

-

2025 How to Choose the Right Knitting Machine Parts for Your Projects

-

Top 5 Essential Circular Knitting Machine Accessories for Perfect Creations

-

10 Best Circular Knitting Machine Parts for Optimal Performance

-

Top 10 Essential Machines and Parts Every Manufacturer Should Know

-

Top 10 Tips for Buying Cheap Knitting Machines That Save You Money

-

Best Knitting Machines for Beginners 10 Top Picks to Start Your Craft Today