Top 10 Essential Machines and Parts Every Manufacturer Should Know

In the modern manufacturing landscape, understanding the machinery and components that drive production processes is crucial for success. The interplay between machines and parts defines productivity, efficiency, and innovation within manufacturing operations. Every manufacturer, regardless of size or sector, should be equipped with knowledge about essential machines and parts that facilitate their production goals.

From basic machines that handle primary tasks to specialized parts that enhance functionality and efficiency, the right equipment can significantly impact a company's performance. This article delves into the top 10 essential machines and parts every manufacturer should know, offering insights into their roles, applications, and the advantages they bring to manufacturing processes. By familiarizing themselves with these fundamental elements, manufacturers can optimize their operations, reduce downtime, and stay ahead in a competitive industry.

Essential Manufacturing Machines Overview

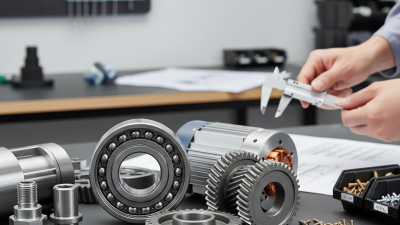

In today's competitive manufacturing landscape, understanding the essential machines and their components is crucial for operational efficiency and productivity. At the forefront of manufacturing are various machines that serve specific functions, ensuring seamless production processes. From CNC machines for precision milling to robotic arms for automation in assembly lines, these technologies streamline workflows and improve output quality. Moreover, components like motors, gears, and bearings play pivotal roles in the machinery’s performance, directly influencing accuracy and speed in manufacturing tasks.

Another critical aspect of manufacturing is the integration of ancillary equipment, such as conveyors and lifting devices. Conveyors facilitate the movement of materials through different stages of production, enhancing workflow efficiency. Lifting devices, on the other hand, are essential for handling heavy loads safely, preventing workplace injuries, and optimizing labor costs. Understanding the capabilities and maintenance requirements of these machines and parts allows manufacturers to make informed decisions, ensuring a robust and responsive manufacturing operation that meets the demands of today's market.

Top 10 Essential Machines and Parts Every Manufacturer Should Know

| Machine/Part | Description | Application | Key Features | Maintenance Tips |

|---|---|---|---|---|

| CNC Machine | Computer Numerical Control machine for precise cutting. | Metalworking, Woodworking, Prototyping | High precision, Programmable, Versatile | Regular calibration, Lubrication, Software updates |

| Laser Cutter | Uses a laser to cut materials. | Sign making, Metal cutting, Fabric cutting | High speed, Minimal waste, No material distortion | Optimal lens cleaning, Check beam alignment |

| 3D Printer | Additive manufacturing to create 3D objects. | Prototyping, Custom parts | Layered construction, Diverse materials | Regular cleaning, Software maintenance |

| Milling Machine | Mill materials using rotary cutters. | Metal and plastic machining | High versatility, Multiple axes | Regular bed leveling, Tool sharpness check |

| Injection Molding Machine | Creates parts by injecting material into a mold. | Mass production of plastic parts | High efficiency, Repeatability | Check for clogs, Monitor temperature controls |

| Press Brake | Bends sheet metal into desired angles. | Sheet metal fabrication | Precision bending, Adjustable settings | Lubrication, Inspect tooling |

| Robot Arm | Automates tasks with programmable movements. | Assembly, Welding, Material handling | High flexibility, Precise control | Routine calibration, Electrical checks |

| Lathe Machine | Removes material from a workpiece that rotates. | Cylindrical parts manufacturing | Versatile, Wide range of operations | Tool wear checks, Consistent lubrication |

| Grinding Machine | Uses abrasive wheels for finishing operations. | Finishing and sharpening applications | Smooth finishes, Precision | Wheel dressing, Regular cleaning |

Key Components of Manufacturing Equipment

In the world of manufacturing, understanding the key components of machinery and equipment is crucial for maintaining efficiency and productivity. Essential parts include motors, drives, sensors, and controllers. Motors generate the necessary motion, while drives regulate speed and torque, enabling precise operation. Sensors play a vital role in monitoring parameters such as temperature and pressure, ensuring safe and optimal functioning of equipment. Finally, controllers orchestrate the actions of these components, allowing for automation and integration within manufacturing processes.

When evaluating machinery, manufacturers should also consider regular maintenance of these components. Tips for maintaining motors include routine cleaning and lubrication, which can prolong their lifespan and prevent unexpected shutdowns. Furthermore, regular calibration of sensors can ensure that the data collected remains accurate, facilitating better decision-making on the production line.

Another area that cannot be overlooked is the significance of safety components. Emergency stops, safety interlocks, and guards are integral to protecting both machines and personnel. Investing in high-quality safety parts not only complies with regulations but also promotes a culture of safety within the manufacturing environment, contributing to overall operational efficiency and employee well-being.

Critical Maintenance Practices for Manufacturing Machines

Effective maintenance practices are crucial for manufacturers looking to optimize the performance and longevity of their machines. Regular inspections should be a foundational practice in any manufacturing environment. These inspections help to identify wear and tear, potential mechanical failures, and ensure that all components operate within their defined parameters. Incorporating a scheduled checklist can assist operators in systematically monitoring key aspects of machinery, such as lubrication levels, alignment, and proper functioning of safety features.

In addition to routine inspections, preventive maintenance is essential for reducing unexpected downtime. This approach involves not only replacing worn-out parts before they cause a breakdown but also conducting necessary recalibrations and adjustments to maintain optimal performance levels. Staff should be trained to recognize the signs that indicate when a machine requires maintenance, such as unusual noises or changes in output quality. By fostering a proactive maintenance culture, manufacturers can significantly enhance the efficiency of their operations and mitigate the risk of costly production interruptions.

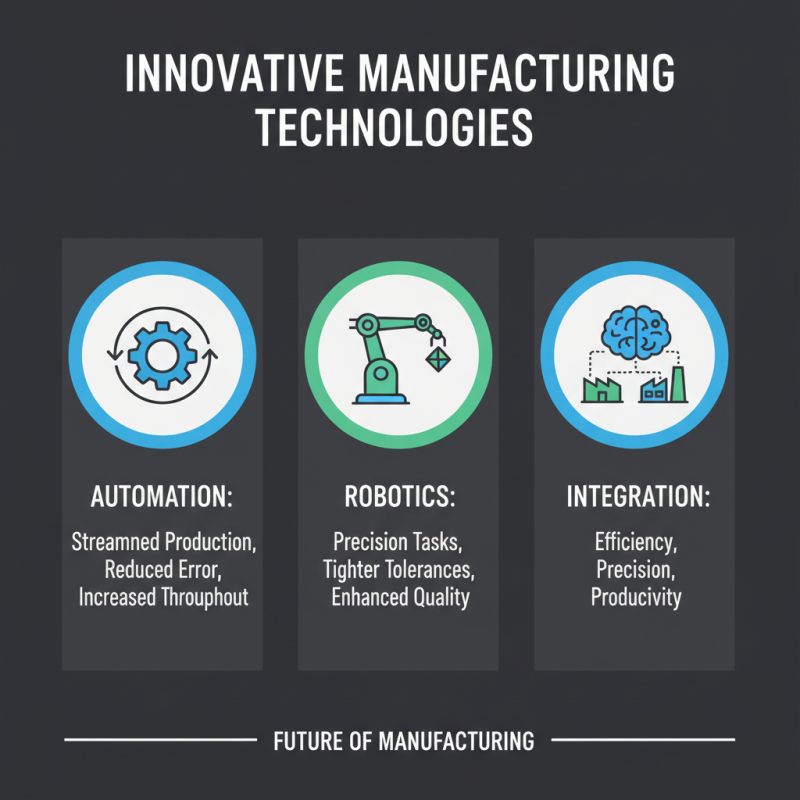

Innovative Technologies in Manufacturing Parts

In the rapidly evolving landscape of manufacturing, innovative technologies play a crucial role in enhancing efficiency, precision, and productivity. One of the most significant advancements includes the integration of automation and robotics. Automation streamlines production processes, reducing human error and increasing throughput. Meanwhile, robotics facilitate complex tasks that require high levels of precision, enabling manufacturers to achieve tighter tolerances and better product quality.

Another transformative technology is additive manufacturing, commonly known as 3D printing. This technique allows for the creation of intricate parts directly from digital models, reducing waste and enabling rapid prototyping. It empowers manufacturers to produce custom components on-demand, which not only shortens lead times but also provides the flexibility to adapt designs swiftly in response to market demands. Furthermore, the rise of smart manufacturing, driven by the Internet of Things (IoT) and data analytics, is revolutionizing how manufacturers monitor performance and maintain equipment, resulting in predictive maintenance and optimized operations. Together, these innovative technologies are reshaping the manufacturing landscape, equipping manufacturers with tools to thrive in a competitive environment.

Future Trends in Manufacturing Machinery and Parts

As the manufacturing landscape continues to evolve, emerging technologies are reshaping the machinery and parts industry. Automation and artificial intelligence have become increasingly integral to manufacturing processes, enabling companies to enhance efficiency and reduce operational costs. Predictive maintenance powered by AI algorithms allows manufacturers to anticipate equipment failures before they occur, minimizing downtime and extending the lifespan of machines. This shift towards smart manufacturing signifies a move from reactive to proactive operational strategies.

Moreover, sustainability is becoming a central theme in the development of manufacturing machinery and parts. Manufacturers are focusing on energy-efficient machines that utilize less power and produce lower emissions. The introduction of biodegradable materials for machine components reflects a growing commitment to environmental responsibility. Additionally, additive manufacturing techniques, such as 3D printing, are enabling more sustainable production methods by reducing waste and allowing for the creation of complex parts with minimal resource consumption. These trends indicate a significant transformation in manufacturing, driven by technology and a focus on sustainability, thereby redefining how products are conceived and produced in the future.

Related Posts

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

How to Choose the Right Machine Parts for Your Equipment Needs

-

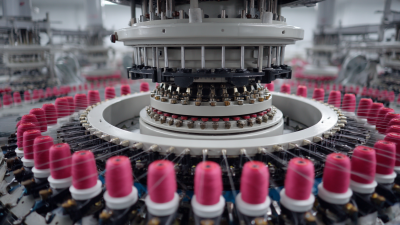

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

2025 Top 10 Circular Knitting Machines to Transform Your Production Efficiency

-

How to Choose the Best Circular Rib Knitting Machine for Your Needs

-

Top 10 Best Circular Rib Knitting Machines for Quality Production