10 Essential Tips for Choosing the Right Machine and Parts for Your Business

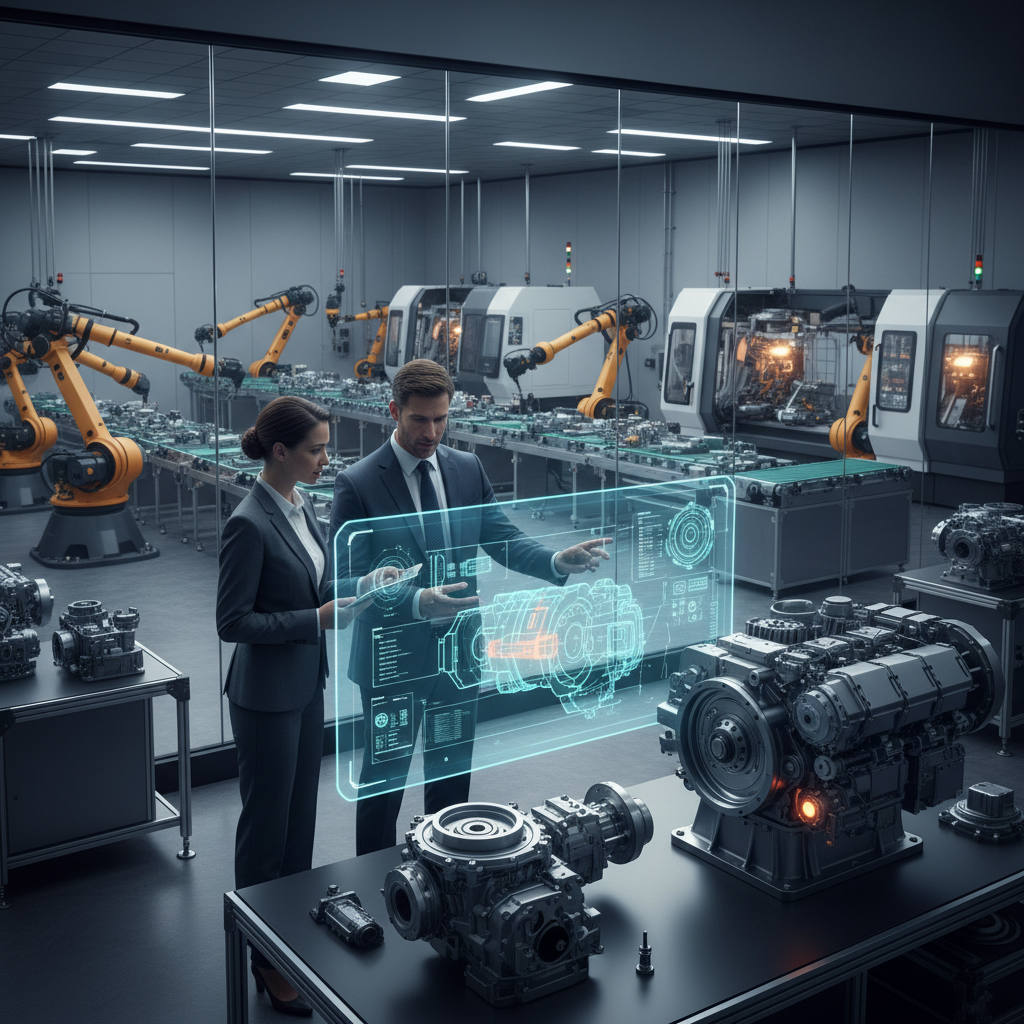

Choosing the right machine and parts for your business is a critical decision that can significantly impact productivity, efficiency, and ultimately, profitability. In today’s competitive landscape, understanding what to consider when selecting these essential tools can make all the difference. Businesses face a myriad of options, and navigating through these choices requires strategic thinking and a clear understanding of your operational needs.

Moreover, the right machine and parts not only enhance performance but also ensure long-term reliability and reduce maintenance costs. Each element, from the specific features of the machine to the quality of its components, plays a pivotal role in determining how well your business can meet its demands.

By following a set of essential tips, entrepreneurs and managers will be better equipped to make informed decisions that align with their goals and work processes. This guide aims to outline the most important considerations to help you choose wisely, ensuring your machinery investments pay off in the long run.

Identifying Your Business Needs and Machine Requirements

When selecting machinery and parts for your business, it is crucial to start by identifying your specific needs. Different applications require various functionalities and specifications, so a thorough assessment of your operational processes is essential. Consider the volume of production, the nature of the materials being used, and the precision required for your tasks. Engaging with your team to gather insights on daily challenges can also highlight the features you need most in your machinery.

Once you have a clear understanding of your business requirements, you can begin to evaluate machines that fulfill those criteria. Pay attention to the reliability and performance history of potential options. Researching manufacturers and their reputations will ensure you are investing in quality machinery. Additionally, consider the availability of spare parts and support services, as this can significantly impact your operational efficiency and downtime in case of repairs or maintenance needs.

Prioritizing these aspects will ultimately lead to better decision-making regarding the machines and parts that align with your business goals.

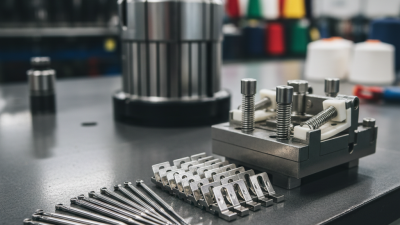

Evaluating Quality and Reliability of Machinery and Parts

When evaluating the quality and reliability of machinery and parts for your business, several critical factors come into play. According to a report by Machinery Information Systems, nearly 70% of machine-related failures are attributed to improper maintenance or the use of subpar parts. This underscores the importance of choosing suppliers that adhere to strict manufacturing standards and provide detailed documentation of their quality control processes. Look for certifications such as ISO 9001, which indicates a commitment to consistent quality and performance.

In addition, performance metrics should be a key consideration. A study from the National Association of Manufacturers found that businesses reporting higher machinery reliability experience an average increase of 15% in production efficiency. It is also vital to assess the warranty and support options available for the equipment. A robust warranty not only reflects a manufacturer’s confidence in their product but also safeguards your investment against potential defects. Engaging with suppliers that offer reliable after-sales support can significantly enhance your operational uptime and overall productivity.

Understanding Maintenance and Support Options

When selecting machinery and parts for your business, understanding maintenance and support options is crucial for ensuring smooth operations. A reliable maintenance plan can significantly reduce downtime and extend the lifespan of your equipment. It's essential to evaluate the manufacturer's support services, including warranty coverage, availability of spare parts, and the responsiveness of their customer service. A strong support system can make a substantial difference in how quickly your business can resolve issues as they arise.

In addition to evaluating support options, businesses should consider preventive maintenance services. These services can help identify potential problems before they escalate, allowing for timely intervention. Look for suppliers who offer comprehensive maintenance agreements that include regular inspections, maintenance schedules, and training for your staff. Choosing machinery with accessible technical documentation and online resources will further empower your team to troubleshoot and perform regular upkeep, ensuring your operations remain efficient and productive.

Maintenance and Support Options for Machinery

Comparing Costs and Value for Your Investment

When considering the right machine and parts for your business, it's crucial to

compare costs and value to ensure a wise investment.

Initially, businesses should not solely focus on the upfront costs of machinery; instead, they need to evaluate

the long-term value that these machines can provide.

A lower purchase price may seem attractive, but if the machine is less efficient or requires

frequent repairs, the overall expenditure can surpass that of a

higher-quality option.

Moreover, assessing the total cost of ownership is

essential. This includes maintenance costs, energy consumption, and potential downtime during repairs.

By calculating these variables, companies can make a comprehensive cost-benefit analysis that

reflects the true value of the investment. Additionally, considering warranties and service agreements

can safeguard against unexpected costs, further influencing the decision-making process.

Ultimately, striking the right balance between

initial cost and value derived from the machine ensures sustainable growth for the business in the long run.

Researching Suppliers and Their Reputation in the Market

When selecting machinery and parts for your business, understanding the reputation of suppliers is crucial. A reliable supplier not only sells quality products but also provides the necessary support and service to ensure your operations run smoothly. Begin your research by looking for suppliers with a strong track record in your industry. Online reviews, testimonials from other businesses, and word-of-mouth recommendations can offer valuable insights into their reliability and customer service.

Furthermore, consider a supplier's longevity in the market. Companies that have been operational for many years often have established practices and relationships with their customers, reflecting stability and trustworthiness. Don’t hesitate to inquire about their sourcing practices and quality control measures. This can help you gauge their commitment to providing top-notch products. Engaging with suppliers directly, asking them about their past projects, and requesting references can also enhance your understanding of their reputation, ensuring that you make a well-informed choice for your business needs.

Related Posts

-

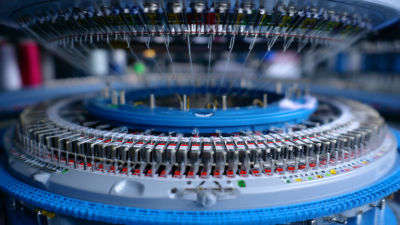

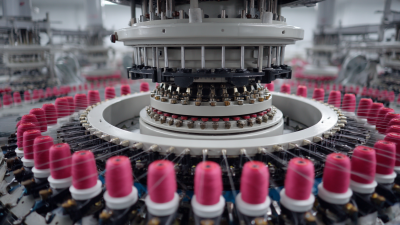

Top 5 Essential Circular Knitting Machine Accessories for Perfect Creations

-

10 Best Circular Knitting Machine Parts for Optimal Performance

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

2025 Top 10 Circular Knitting Machines to Transform Your Production Efficiency

-

Top 5 Best Used Knitting Machines for Quality and Affordability

-

2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth