What is a Knitting Jacquard Machine and How Does It Work

The knitting jacquard machine represents a remarkable advancement in textile technology, allowing for intricate patterns and designs to be produced with ease and precision. By utilizing a specialized mechanism that employs a series of hooks and needles, the knitting jacquard machine enables the creation of complex motifs that were once painstakingly crafted by hand. This innovation not only enhances the aesthetic appeal of knitted fabrics but also significantly increases production efficiency, making it a crucial tool in the fashion and textile industries.

As we delve into the workings of the knitting jacquard machine, we will explore its fundamental components and the underlying technology that allows for the seamless integration of different yarns and colors within a single fabric. The interplay of various techniques employed in jacquard knitting leads to unique fabric textures and visual depth, opening up a world of creative possibilities for designers and manufacturers alike. Understanding how this machine operates reveals the synergy between craftsmanship and technology, highlighting its pivotal role in modern fabric production.

Overview of Knitting Jacquard Machines

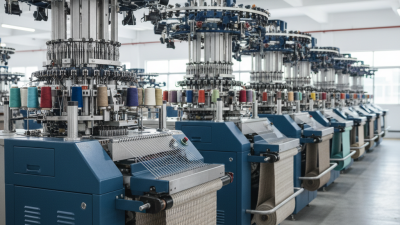

Knitting Jacquard machines are specialized textile machines that enable the production of intricate patterns and designs in knitted fabrics. These machines utilize a unique mechanism that allows for the control of multiple yarns, delivering a wide variety of colors and patterns with precision. The Jacquard technique, which dates back to the early 19th century, revolutionized textile manufacturing by enabling designers to create complex motifs without the need for intricate manual labor, thus streamlining the production process significantly.

The working principle of a Knitting Jacquard machine centers around the use of a programmable system that controls individual needles and yarn feeds. Each needle can be elevated or lowered based on the desired pattern, allowing different yarns to be engaged at specific intervals. This capability makes it possible to produce detailed designs, including geometric shapes, floral patterns, or even textures, all within a single knitted piece. The integration of digital technology has further enhanced these machines, enabling real-time adjustments and more complex designs, thereby increasing both creativity and efficiency in the textile industry.

Key Components of a Knitting Jacquard Machine

Knitting Jacquard machines are intricate textile apparatuses that produce complex multi-colored patterns using advanced techniques. The functionality of these machines hinges on a few key components that contribute to their efficiency and versatility. One of the most crucial parts is the jacquard mechanism itself, which controls the needles that knit the yarn into specific designs. This mechanism is often operated through a series of punched cards or electronic technology that allows for precise control over each stitch. Reports indicate that over 90% of high-end textile producers utilize some form of jacquard technology, highlighting its importance in modern textile manufacturing.

Another essential component is the yarn feeder, which ensures a consistent supply of yarn for the knitting process. This component must be finely tuned to handle various yarn types and weights, thereby accommodating different design specifications. In recent studies, it was shown that optimal yarn tension can reduce material waste by up to 25%, making it a significant factor for manufacturers aiming for sustainability.

Tips: When working with a knitting jacquard machine, regularly inspect the jacquard mechanism and yarn feeders to prevent issues during production. Additionally, keeping the machine well-lubricated and clean can enhance its lifespan and operational efficiency. Engaging in consistent maintenance can yield better output quality and reduce costs in the long run.

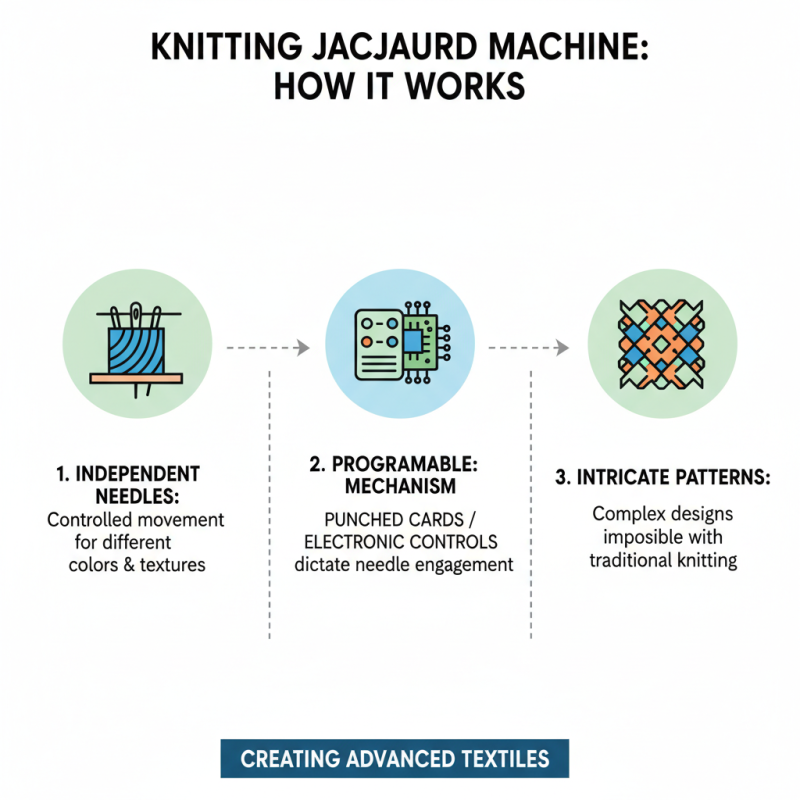

How a Knitting Jacquard Machine Operates

A knitting Jacquard machine operates by using a programmable mechanism that allows it to create intricate patterns and designs on knitted fabric. At its core, the machine employs a system of controlled needles that can move independently. This independent movement is crucial because it enables the knitting of different colors and textures in a single piece of fabric. The Jacquard system utilizes a series of punched cards or electronic controls to dictate which needles should engage with the yarn at any given time, thus producing complex patterns that would be virtually impossible with traditional knitting methods.

The operation begins with the selection of a design, which is translated into a binary code that the machine can understand. The electronic controls read this code and adjust the needle movements according to the desired pattern. As the yarn is fed through the machine, the selected needles lift and lower, creating loops that form stitches in various colors and materials. This precision allows for the replication of detailed images or motifs directly onto the fabric, ensuring high-quality results and a wide range of design possibilities. By continually adapting the needle movements, the Jacquard machine can produce elaborate textiles efficiently, making it an essential tool in the modern textile industry.

Applications of Knitting Jacquard Machines in Textiles

Knitting Jacquard machines play a pivotal role in the textile industry, particularly in the production of intricate patterns and designs. These advanced machines enable manufacturers to create complex fabrics with high precision, thereby enhancing the aesthetic appeal of textiles. According to a report by Textiles Intelligence, the global market for Jacquard machines is projected to grow at a CAGR of 5.2% through 2025, emphasizing their increasing importance in contemporary textile manufacturing.

The applications of Knitting Jacquard machines extend beyond simple garment production. They are utilized in creating upholstery fabrics, home textiles, and technical textiles, showcasing their versatility. This technology is particularly beneficial in producing personalized and customized fabrics, catering to consumer demands for unique designs. The ability to produce high-quality, intricate patterns at scale makes these machines essential in meeting the evolving trends in fast fashion and luxury textiles alike. As industries continue to embrace automation and advanced textile technology, the demand for Knitting Jacquard machines is expected to rise, reinforcing their crucial role in innovative textile applications.

Benefits of Using a Knitting Jacquard Machine in Production

Knitting Jacquard machines revolutionize textile production by allowing for intricate and customized designs to be incorporated into fabrics. One of the primary benefits of using a Jacquard machine is its ability to produce complex patterns with ease and precision. This capability significantly reduces the time and labor needed to create elaborate knitwear compared to traditional methods. As a result, manufacturers can respond quickly to market demands and offer unique items that stand out in a competitive landscape.

Another advantage of these machines is enhanced fabric quality. With automated design processes, consistent tension and stitch quality are maintained throughout production, leading to fewer defects and waste. This translates to higher customer satisfaction and can enhance a brand’s reputation for quality. Additionally, the versatility of Jacquard machines allows for experimentation with a variety of yarns and materials, enabling producers to create diverse product lines.

**Tips:** When implementing Jacquard technology, ensure that your design team is well-trained in the software used to create patterns. Prototyping designs before mass production can also help in identifying potential issues early in the process. Lastly, regularly maintaining your machines will ensure longevity and consistent performance.

Related Posts

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

-

2025 How to Choose the Right Knitting Machine Parts for Your Projects

-

How to Choose the Best Rib Knitting Machine for Your Projects

-

How to Choose the Right Machine Parts for Your Equipment Needs

-

Top 10 Best Circular Rib Knitting Machines for Quality Production