2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth

The landscape of machine parts manufacturing is undergoing significant transformation, driven by technological advancements and evolving market demands. According to a recent market report by Smith & Associates, the global machine parts industry is projected to grow by 10% annually over the next five years, reaching an estimated market size of $500 billion by 2025. This growth is fueled by the increasing adoption of automation and robotics, which are essential for enhancing operational efficiency and productivity across various sectors.

Moreover, Industry Week reports that investments in smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence, are revolutionizing how machine parts are designed, produced, and maintained. These innovations facilitate not only optimized manufacturing processes but also improved supply chain management. As companies embrace these trends, understanding the top insights into machine parts will become paramount for stakeholders aiming to strategically position themselves within the evolving industry landscape. By exploring the top 10 trends influencing machine parts in 2025, this paper aims to provide valuable insights that guide decision-making and investment in the future of the machine parts sector.

Emerging Technologies Impacting Machine Parts Manufacturing in 2025

The machine parts manufacturing industry is on the brink of a transformative shift due to emerging technologies, driving an anticipated growth of 10% by 2025. Innovations such as additive manufacturing (3D printing), artificial intelligence (AI), and the Internet of Things (IoT) are reshaping how components are designed, produced, and maintained. According to a recent report from McKinsey, the adoption of AI in manufacturing is projected to increase productivity by up to 40%, enabling companies to streamline operations and reduce costs significantly.

Tips: To stay ahead in this evolving landscape, companies should invest in upskilling their workforce in new technologies. Implementing continuous training programs focused on digital skills can enhance team capabilities and ensure smooth transitions to advanced manufacturing processes.

Additionally, the integration of IoT in machine parts manufacturing allows for real-time monitoring and predictive maintenance. Siemens reports that this technology can potentially decrease downtime by 20-30%, resulting in more efficient production schedules. Companies looking to harness these benefits should consider collaborating with tech partners to develop customized IoT solutions tailored to their specific needs.

Key Market Drivers Contributing to the 10% Growth Rate in the Industry

In 2025, the machine parts industry is set to experience a significant 10% growth rate, driven by several critical market factors. One of the primary drivers is the increasing demand for automation across various sectors, including manufacturing and logistics. As industries strive for greater efficiency and productivity, the reliance on advanced machine parts that facilitate automation is expected to rise.

Tips for businesses looking to capitalize on this trend include investing in high-quality components that ensure durability and reliability. Companies should also prioritize research and development to innovate new products tailored to meet evolving customer needs. Additionally, fostering partnerships with technology providers can enhance product offerings and keep pace with the rapidly changing landscape.

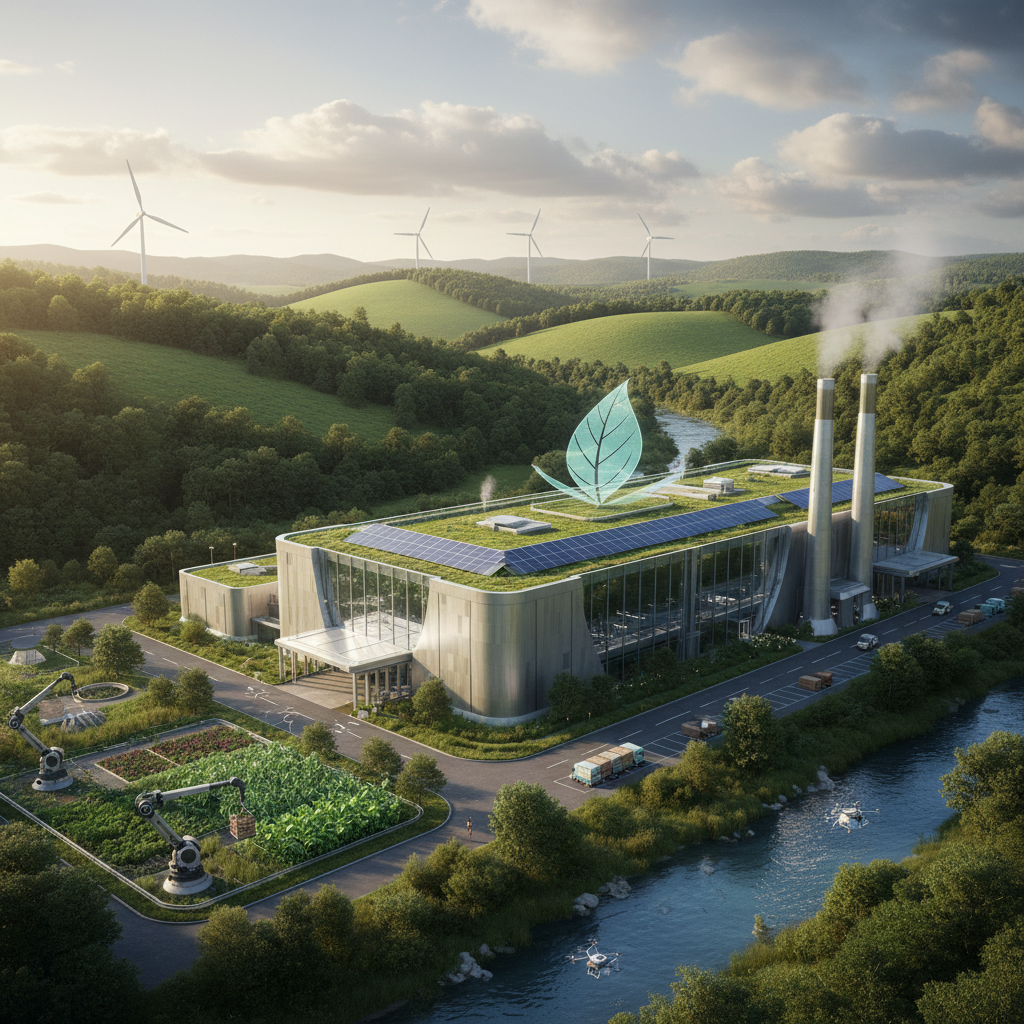

Another key contributor to the industry's growth is the rise of sustainable manufacturing practices. As organizations shift their focus to environmentally friendly processes, the demand for machine parts that support sustainability, such as energy-efficient components and recyclable materials, is increasing. To stay competitive, companies should consider adopting sustainable practices and highlighting them in their marketing strategies. Building a reputation for sustainability can attract environmentally conscious consumers and significantly improve market positioning.

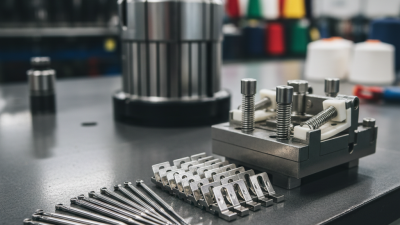

Top 5 Innovative Materials Revolutionizing Machine Component Design

The machine parts industry is poised for significant growth, with projections indicating a remarkable 10% increase by 2025. Central to this expansion is the introduction of innovative materials that are transforming the design and functionality of machine components. According to recent reports from industry leaders such as Fortune Business Insights, advanced materials like carbon fiber composites, titanium alloys, and high-performance polymers are at the forefront of this revolution, offering unprecedented strength-to-weight ratios and improved durability.

Carbon fiber composites, for instance, are increasingly being utilized for their lightweight properties and superior mechanical performance. They can reduce component weight by up to 50%, which directly enhances energy efficiency in various applications, from aerospace to automotive sectors. Meanwhile, titanium alloys are gaining traction for their exceptional resistance to corrosion and heat, making them ideal for high-stress environments. Data from the MarketsandMarkets report emphasizes that the demand for titanium in industrial applications is expected to grow by over 6% annually through 2025, underscoring its importance in component manufacturing.

In addition, high-performance polymers such as PEEK and PEI are revolutionizing designs by enabling the creation of intricate geometries that enhance functionality while reducing overall material usage. These materials not only improve performance but also contribute to sustainable practices by minimizing waste. As these innovative materials become more prevalent, they will undoubtedly play a pivotal role in shaping the future of machine component design, driving efficiencies and supporting the overall growth of the industry.

The Role of Automation and AI in Enhancing Production Efficiency

The integration of automation and artificial intelligence (AI) in the machine parts industry is poised to significantly enhance production efficiency, driving overall industry growth. According to a recent report by MarketsandMarkets, the global market for industrial automation is projected to reach $300 billion by 2025, growing at a CAGR of 9.5%. This surge is largely attributed to the increasing demand for high-quality products and the need for reduced production costs. By implementing AI-driven processes, manufacturers can streamline operations, minimize human error, and improve decision-making through predictive analytics.

In addition to cost savings, automation is changing the landscape of workforce dynamics within production facilities. A study from McKinsey suggests that up to 45% of work activities could be automated, allowing skilled labor to focus on complex problem-solving and innovation. Organizations that embrace these technologies report not only improved efficiency but also a stronger competitive position in the market. As machine parts manufacturers leverage AI and automation, they stand to benefit from optimal operational performance, ultimately driving a 10% growth rate in the industry by 2025.

2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth

This chart illustrates the projected growth in the machine parts industry by 2025, highlighting the impact of automation and AI on production efficiency across various sectors.

Sustainability Trends Shaping the Future of Machine Parts Industry Practices

The machine parts industry is poised for significant growth, with trends focused on sustainability leading the charge. A notable projection indicates that the global sustainable tourism market is expected to reach USD 13 trillion by 2033, demonstrating a remarkable CAGR of 13.5%. This shift towards sustainability is reshaping industry practices, pushing companies to adopt greener manufacturing processes and materials. The drive for eco-friendly solutions is no longer an option but a necessity as businesses aim to meet stringent environmental regulations and consumer expectations.

Moreover, the integration of Artificial Intelligence (AI) and Machine Learning (ML) into production processes has been highlighted as a crucial factor in enhancing production efficiency while supporting sustainable development. Research illustrates that these advanced technologies are contributing to reduced waste and optimized resource utilization, which are essential for achieving long-term sustainability goals. As companies in the machine parts sector recognize the importance of aligning their operations with these trends, the industry is expected to experience an impressive 10% growth, reflecting a commitment to innovative and responsible practices.

Related Posts

-

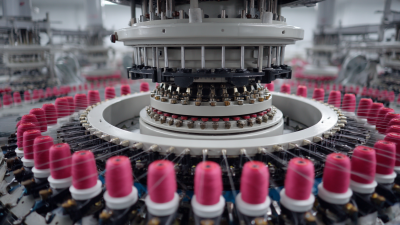

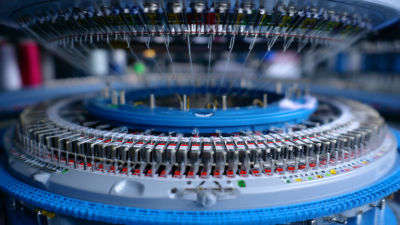

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

2025 Top 10 Circular Knitting Machines to Transform Your Production Efficiency

-

10 Best Circular Knitting Machine Parts for Optimal Performance

-

Top 5 Best Used Knitting Machines for Quality and Affordability

-

Top 5 Essential Circular Knitting Machine Accessories for Perfect Creations