2026 Top Circular Knitting Machine Parts You Need to Know?

The world of textiles is evolving, with an increasing focus on efficiency and sustainability. The demand for high-quality fabrics is driving the innovation of circular knitting machine parts. In 2022, the global textile machinery market was valued at approximately $24 billion, with considerable growth expected in the coming years.

Advanced circular knitting machines are enhancing productivity. They can produce various fabrics, meeting diverse consumer needs. However, many manufacturers often overlook the importance of specific machine parts. A report from Textile World highlights that poor maintenance of circular knitting machine parts can lead to costly downtime and decreased output quality.

Understanding essential parts, such as yarn feeders and needle systems, is crucial. More manufacturers are exploring automated technologies, but not all parts adapt well. This knowledge gap may hinder production efficiency. Companies must invest in training and awareness of circular knitting machine parts to remain competitive. An informed approach prevents issues and drives success in this fast-paced industry.

Key Components of Circular Knitting Machines Explained

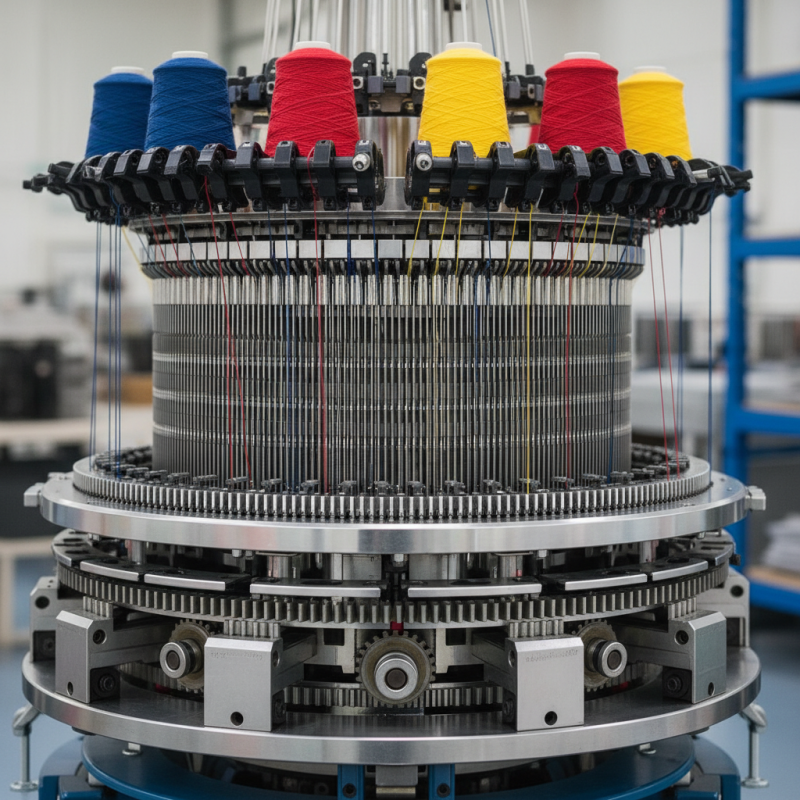

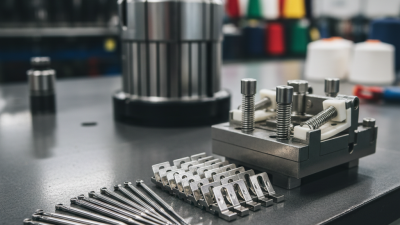

When diving into the world of circular knitting machines, understanding their key components is crucial. The needle, for example, serves as the heart of the machine. This small yet vital part dictates the fabric's quality. A worn or faulty needle can ruin an entire production run. Manufacturers often overlook this, leading to significant waste.

Next, the cylinder is another essential part. It holds the needles in place and controls the fabric's gauge. A misalignment in the cylinder can create uneven loops. Operators need to regularly check for accuracy. Attention to detail here can save time and resources. Additionally, the yarn feeder plays a vital role. It ensures a consistent yarn supply. An inconsistent feed can cause tension issues. This can lead to defects that might be hard to detect early on.

Understanding these components is just the starting point. Each part requires careful maintenance and frequent checks. Ignoring this can lead to frustrating outcomes. As technology evolves, so do the expectations of quality. Regular reflection on these components can enhance overall efficiency.

2026 Top Circular Knitting Machine Parts You Need to Know? - Key Components of Circular Knitting Machines Explained

| Part Name | Function | Material | Maintenance Tips |

|---|---|---|---|

| Needle | Creates loops in yarn to form fabric | Steel | Regular cleaning; replace when dull |

| Cam | Controls the movement of needles | Aluminum | Lubrication; check for wear and tear |

| Sinker | Holds the fabric in place and contributes to loop formation | Bronze | Inspect regularly; replace if bent |

| Driving Mechanism | Provides power to the machine for operation | Various metals and plastics | Check alignment; ensure proper lubrication |

| Take-Up Roller | Rolls up the finished fabric | Plastic | Monitor tension; clean surface regularly |

Understanding Yarn Feed Mechanisms in Circular Knitting Machinery

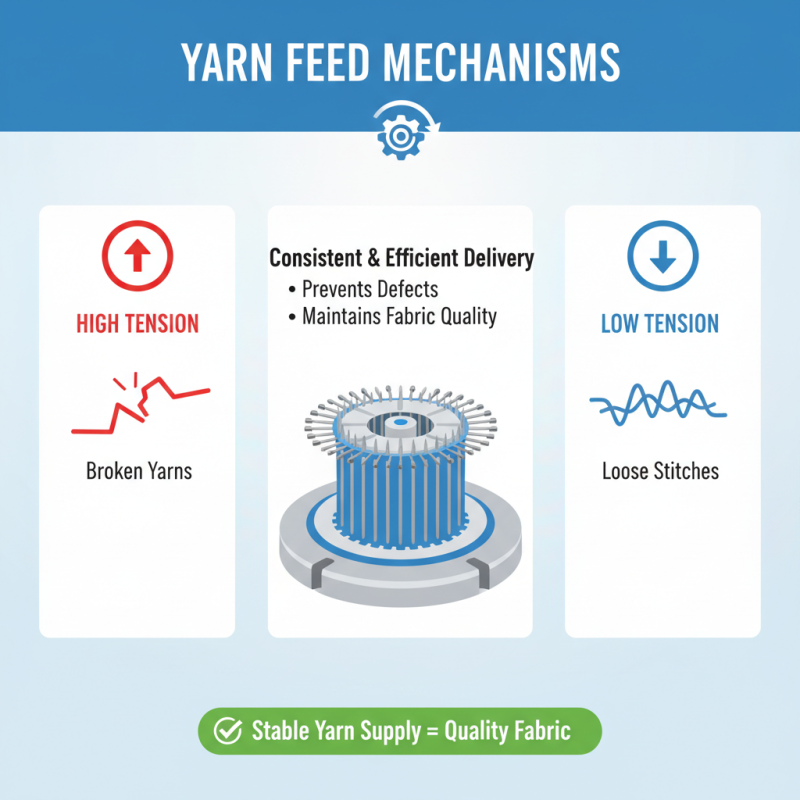

Yarn feed mechanisms play a crucial role in circular knitting machines. These systems ensure that yarn is delivered consistently and efficiently during the knitting process. A stable supply of yarn prevents defects and maintains fabric quality. When yarn-tension control is poor, issues arise. For instance, excess tension can lead to broken yarns, while low tension may result in loose stitches.

Different types of yarn feed systems exist. Some machines use pneumatic feeders, while others utilize mechanical versions. Each has its advantages and drawbacks. Pneumatic systems can offer a precise and adjustable flow of yarn. However, they may require regular maintenance to avoid air leaks and performance drops. Mechanical systems can deliver a strong grip but may struggle with delicate fibers.

It is essential to choose the right mechanism for your specific needs. A mismatch can lead to wasted material and time. Testing various setups and gathering feedback from operators is beneficial. This process creates a better understanding of how different systems impact final output. Continuous improvement is key in the fast-evolving textile industry. Finding the perfect balance in yarn feed can make a significant difference in minimizing production challenges.

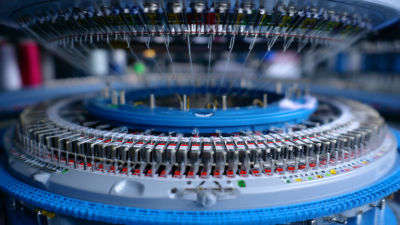

The Role of Needle Systems in Circular Knitting Efficiency

In circular knitting, needle systems play a vital role in efficiency. These systems determine how well yarn is used. A well-designed needle can enhance the knitting speed. Conversely, subpar designs slow down production. This inefficiency can lead to increased waste and costs.

Consider the types of needles you use. Different materials impact durability and performance. Stainless steel needles are popular for their longevity. However, they may not always be the best choice for every fabric type. Testing various needle systems is essential. Sometimes, a simple change can greatly improve output.

Tips: Regular maintenance is crucial for needle systems. Clean them often to prevent debris buildup. Also, monitor the tension settings. Too tight or loose can affect the final product. Experiment with different configurations but stay mindful of changing conditions. Small adjustments can yield large results.

2026 Top Circular Knitting Machine Parts: Impact of Needle Systems on Efficiency

Essential Electronic Controls for Modern Circular Knitting Machines

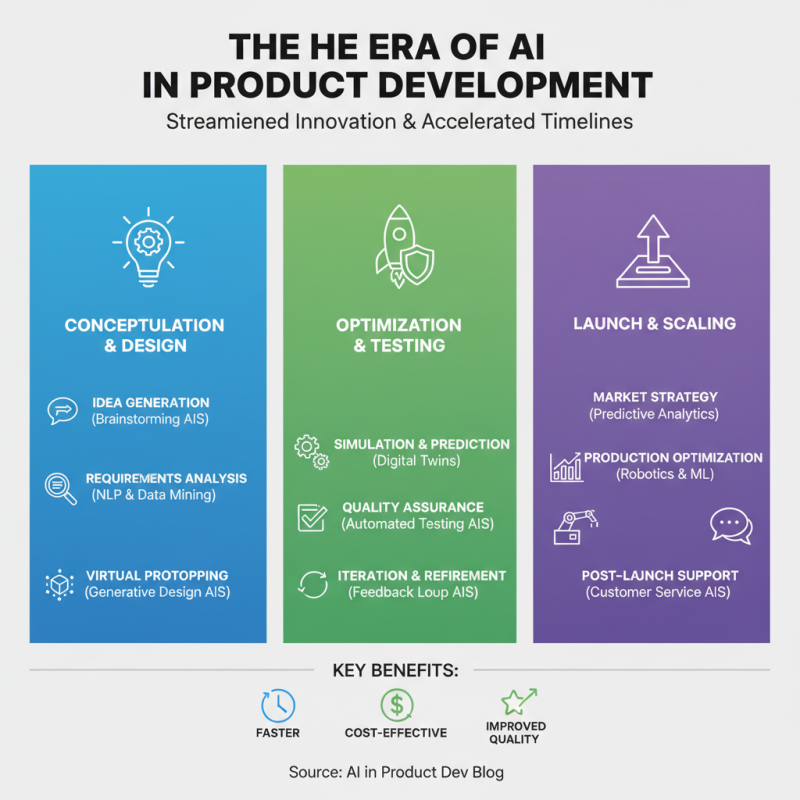

Modern circular knitting machines are becoming increasingly dependent on advanced electronic controls. These controls enhance precision and efficiency in production. They can manage stitch patterns, adjust tension, and optimize speed. This automation reduces the need for manual adjustments.

The electronic control system integrates several components. It includes a user-friendly interface for easy operation. Operators can monitor and tweak settings in real-time. Sensors play a crucial role, providing feedback on yarn tension and machine performance. However, these high-tech features require regular maintenance and updates. Neglecting this can lead to errors and decreased output.

Understanding these controls is essential for anyone in the knitting industry. Training and experience are vital for maximizing the benefits. New users often struggle with the software. It can be overwhelming at first. Effective troubleshooting skills are necessary to ensure smooth operations. Embracing these challenges can lead to significant improvements in production quality.

Maintenance Tips for Prolonging the Lifespan of Circular Knitting Parts

Maintaining circular knitting machine parts is essential for performance. Regular cleaning helps remove dust and debris. Use a soft brush to clean delicate components. This simple act can extend the machine's lifespan by preventing wear and tear.

Lubrication is another key aspect. Applying the right oil to moving parts reduces friction. This keeps the machine running smoothly. However, over-lubrication can attract dust, leading to blockages. Balance is crucial. Consider a routine check every few weeks to ensure optimal function.

Checking for loose screws and worn belts is also vital. Tighten any loose fasteners to avoid sudden failures. Inspect the belts for any signs of fraying. Ignoring these details can lead to bigger problems and costly repairs. Regular attention to these aspects can significantly enhance the durability of your circular knitting equipment.

Related Posts

-

Top 5 Essential Circular Knitting Machine Accessories for Perfect Creations

-

10 Best Circular Knitting Machine Parts for Optimal Performance

-

Top 10 Essential Knitting Machine Parts You Need to Know About

-

Top 10 Essential Machines and Parts Every Manufacturer Should Know

-

Top 10 Tips for Buying Cheap Knitting Machines That Save You Money

-

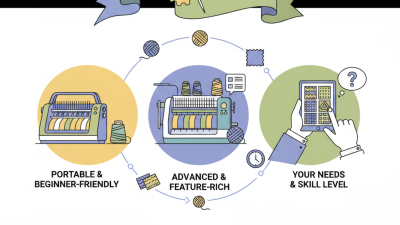

How to Choose the Best Knitting Machine for Home Use in 2025