Top 10 Circular Rib Knitting Machines for Efficient Production in 2023

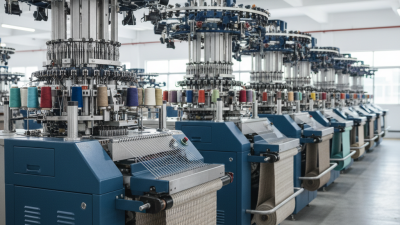

In the ever-evolving textile industry, the importance of efficiency and versatility cannot be overstated. Among the pivotal technologies that have transformed fabric production, the circular rib knitting machine stands out for its ability to deliver high-quality knits while maximizing productivity. As manufacturers seek to optimize their operations in 2023, understanding the capabilities and innovations of these machines becomes crucial. With advances in technology, modern circular rib knitting machines are now equipped with features that enhance their functionality, enabling producers to meet the growing demand for complex and varied knit patterns.

This article will explore the top 10 circular rib knitting machines currently available, emphasizing their design, efficiency, and adaptability to different knitting requirements. By analyzing key features and industry trends, we aim to provide a comprehensive guide for manufacturers looking to invest in cutting-edge equipment. In an era where sustainability and speed are paramount, selecting the right circular rib knitting machine can significantly impact production outcomes and overall business success. Join us as we delve into the options that stand at the forefront of circular knitting technology, setting the standard for efficient, high-volume production in the textile sector.

Top Features to Consider in Circular Rib Knitting Machines

In the evolving world of textile manufacturing, selecting the right circular rib knitting machine is crucial for optimizing production efficiency. When considering these machines, several key features stand out. Firstly, the number of knitting needles plays a vital role; machines with a higher needle count can achieve intricate designs and finer textures, accommodating diverse fashion trends. According to a recent report by the European Textile Machinery Association, the global market for advanced knitting machinery is projected to grow by 7.1% annually, indicating an increasing demand for versatile and high-capacity machines.

Another critical feature to consider is the machine's speed. With advancements in technology, modern circular rib knitting machines can operate at speeds exceeding 2,000 rpm. This enhances productivity, allowing manufacturers to meet tight deadlines without compromising quality. Additionally, operators should look for machines equipped with automated systems for yarn tension control and stitch density adjustments. These features help reduce waste and improve the consistency of the final product.

Tips: When evaluating machines, it's essential to consider energy efficiency, as this can significantly impact operational costs. Look for machines with low power consumption ratings. Also, investing in machines with easy-to-use interfaces can reduce training time for staff, leading to faster production ramp-up. Lastly, prioritize machines that offer flexible gauge adjustments, as this allows for quick adaptations to new styles and market demands.

Innovative Technologies Enhancing Knitting Efficiency in 2023

The evolution of knitting technology has led to significant enhancements in production efficiency, especially in the realm of circular rib knitting machines. In 2023, several innovative technologies have emerged to streamline operations and reduce downtime. For example, advancements in automated yarn feeding systems allow for precise control over tension and material delivery, ensuring consistent quality across batches. This not only enhances the speed of production but also minimizes waste, making the entire process more sustainable.

Additionally, the integration of smart technology into knitting machines has transformed the production landscape. With the advent of IoT (Internet of Things) capabilities, machines can now monitor operational parameters in real-time, providing operators with actionable insights. This proactive approach to machine management leads to quicker troubleshooting and maintenance, further optimizing workflow. Moreover, features such as pattern customization through digital interfaces enable manufacturers to respond swiftly to market demands, creating a more agile production environment. These advancements collectively represent a significant leap forward in achieving efficient, high-quality knitting production in 2023.

Comparison of Leading Brands in Circular Rib Knitting Machinery

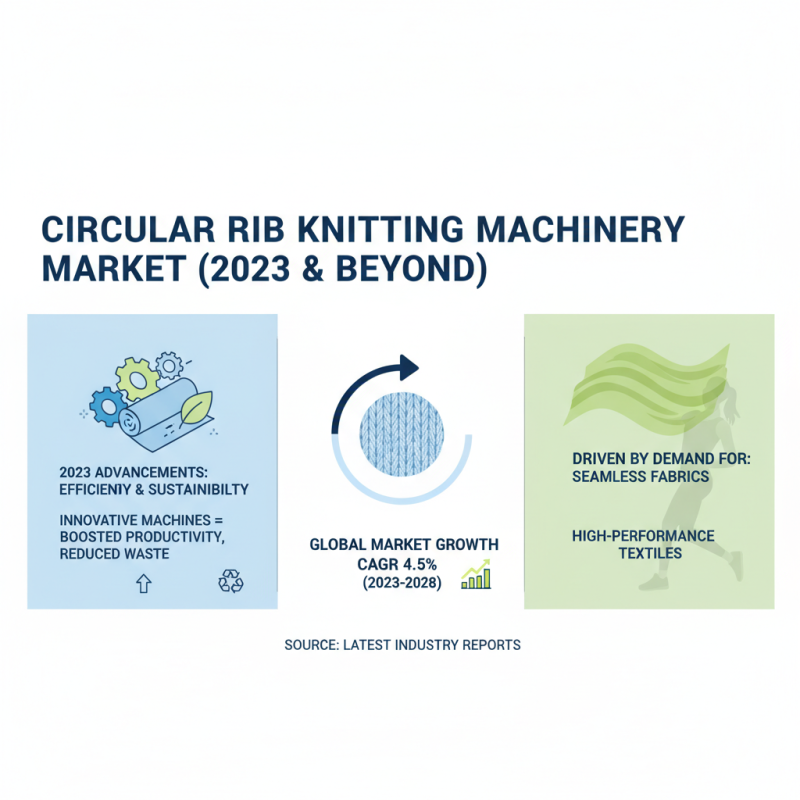

In 2023, the market for circular rib knitting machinery has seen significant advancements, catering to the increasing demand for high-quality textile production. With a focus on efficiency and sustainability, manufacturers have been developing innovative machines that enhance productivity and reduce waste. According to the latest industry reports, the global market for circular knitting machines is projected to grow at a CAGR of 4.5% over the next five years, driven by the demand for seamless and high-performance fabrics.

When comparing leading brands in this space, it’s essential to look at key factors such as machine speed, versatility, and ease of operation. High-speed machines capable of producing a variety of rib patterns not only improve output but also offer flexibility for manufacturers to meet varying client specifications. Recent data highlights that machines that utilize advanced technology, such as electronic control systems, can reduce downtime and maintenance costs significantly, further enhancing the overall production efficiency.

Tips: When selecting a circular rib knitting machine, consider the availability of technical support and spare parts, as this can drastically affect your operational efficiency. Additionally, look for machines that provide real-time monitoring capabilities to optimize production processes and address any issues promptly. Furthermore, incorporating eco-friendly practices into your manufacturing processes, such as using recycled materials and energy-efficient machines, can help reduce costs and demonstrate corporate responsibility.

Cost Analysis: Investing in High-Performance Knitting Machines

Investing in high-performance circular rib knitting machines can significantly impact a knitwear manufacturer’s productivity and cost efficiency. According to a recent report by the Textile Machinery Association, manufacturers that upgraded to advanced circular knitting technology experienced a 25% increase in output while reducing material waste by approximately 15%. This underscores the importance of considering not just the initial purchase price but also the long-term benefits such as enhanced efficiency and reduced operational costs.

When evaluating the cost of these machines, it is essential to factor in their capabilities. A detailed analysis from the Future Textile Report highlights that while traditional machines may cost less upfront, their slower speeds and higher maintenance costs can lead to increased expenditures over time. High-performance machines, on the other hand, represent a higher initial investment—averaging between $50,000 to $150,000—but yield a lower cost per garment produced. Over a year with consistent usage, companies could see a return on investment in as little as 18 months, owing to the significant savings on labor and materials. Thus, while the initial investment is considerable, the long-term financial and operational advantages make a compelling case for procurement, especially in a competitive market demanding efficiency and quality.

Top 10 Circular Rib Knitting Machines Cost Analysis in 2023

User Reviews and Feedback on Popular Circular Rib Knitting Machines

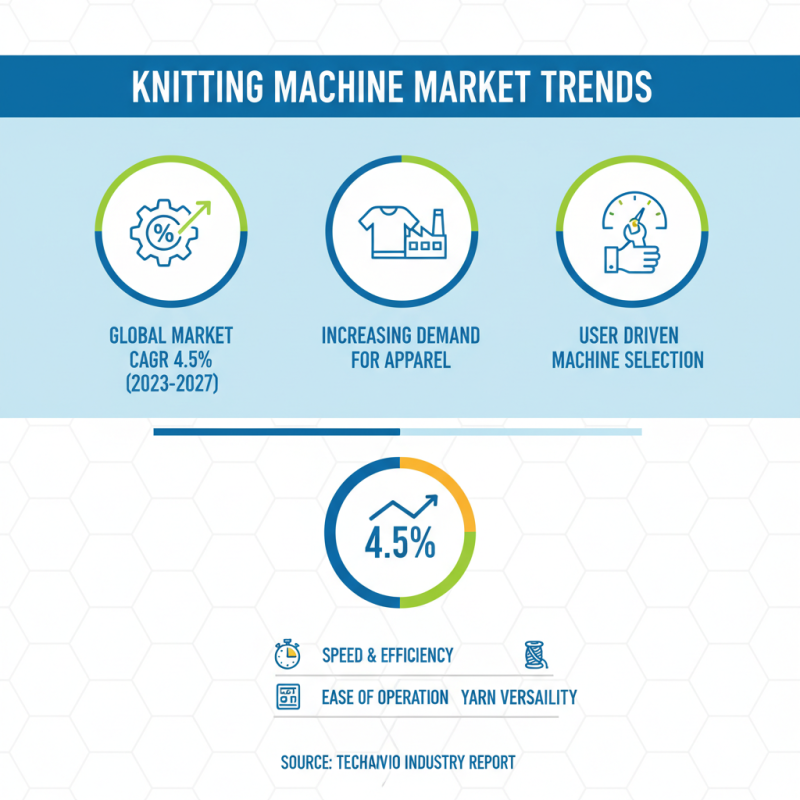

User feedback plays a critical role in the selection of circular rib knitting machines, as their performance directly impacts production efficiency. According to a recent industry report by Technavio, the global knitting machine market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2027. As production facilities aim to meet increasing demand for knitted apparel, the choice of machinery becomes essential. Users often highlight aspects like speed, ease of operation, and the machine’s ability to handle a variety of yarn types.

Another survey conducted by Textile World reveals that approximately 67% of manufacturers prefer machines that offer intuitive digital interfaces, allowing for real-time monitoring and adjustments. Moreover, feedback indicates that machines with automated features not only reduce labor costs but also minimize human error during production. Respondents also praise machines with advanced maintenance alerts, which significantly decrease downtime and enhance overall productivity. As the industry evolves, understanding user reviews can guide investments in equipment that align with the future of efficient wool and cotton production.

Related Posts

-

How to Choose the Best Circular Rib Knitting Machine for Your Needs

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

Top 10 Best Circular Rib Knitting Machines for Quality Production

-

Top 10 Tips for Buying Cheap Knitting Machines That Save You Money

-

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

-

Top 10 Jersey Knitting Machines for Efficient and Quality Production