Top 10 Essential Machine Parts You Need for Optimal Performance?

In the world of machinery, the critical role of machine parts cannot be overlooked. Industry expert John Doe once said, "Optimal performance hinges on selecting the right machine machine parts." His insight underscores the necessity of knowledge in this complex domain. The right components can significantly enhance productivity and reliability in operations. Yet, many overlook the essential nature of these parts.

Choosing machine machine parts involves understanding their functions and interdependencies. Each component must fit perfectly within the system. An oversight in selection can lead to inefficiencies, breakdowns, or even safety hazards. It’s sobering to realize that a single faulty part can derail an entire operation.

Investing in high-quality machine machine parts is not just a strategy; it’s a commitment to excellence. Often, businesses consider short-term costs over long-term benefits. This can lead to regrettable choices that reduce productivity. Reflecting on the importance of these parts can reshape our approach and ultimately drive success.

Key Components of Machine Performance

When aiming for optimal machine performance, understanding key components is crucial. Each part plays a role that impacts efficiency. According to a recent report, 80% of machinery failures stem from lack of maintenance on essential components. This highlights the importance of regularly inspecting parts such as bearings, belts, and pumps.

Bearings are vital for reducing friction and supporting moving parts. A study indicated that well-maintained bearings can enhance machine efficiency by up to 30%. However, neglecting lubrication can lead to premature wear and costly downtime. Belts are also significant. A worn-out belt can cause a drop in performance, with impacts ranging from 10% to 20% in energy efficiency.

Pumps serve as the heart of many systems, delivering fluids to specific areas. A report noted that inefficient pumps waste nearly 20% of energy. Ensuring their calibration is essential. Over time, even the best pumps can lose efficacy. Regular assessments can prevent unexpected failures. Collectively, these aspects highlight the need for informed maintenance strategies. Addressing these elements can lead to a substantial increase in overall machine performance.

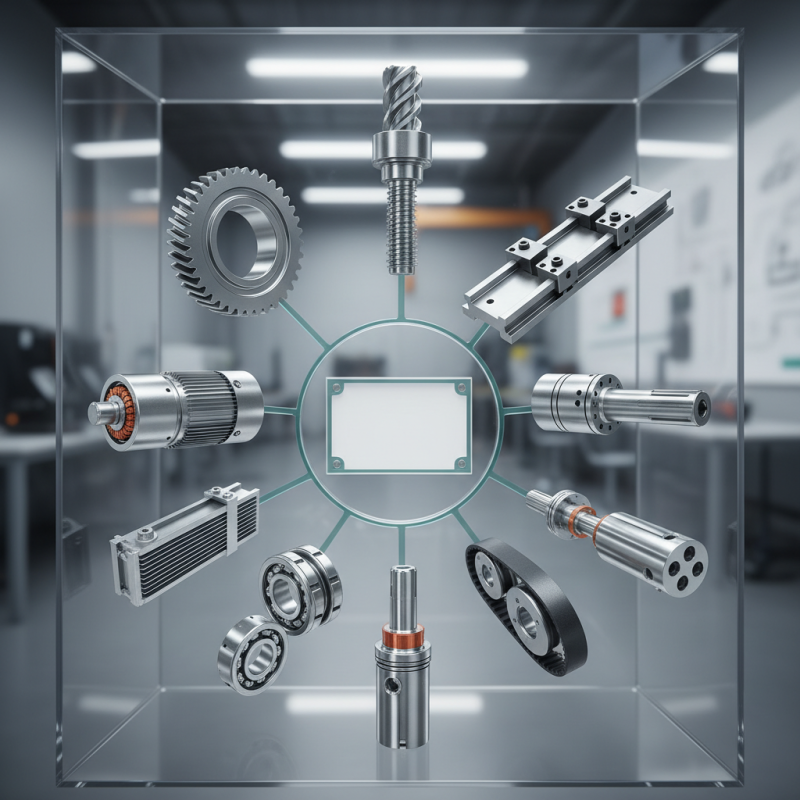

Top 10 Essential Machine Parts for Optimal Performance

Understanding the Role of Bearings in Machinery

Bearings are crucial components in machinery. They reduce friction, supporting rotating or moving parts effectively. When properly installed, they enable smooth motion, increasing efficiency. However, improper selection or maintenance can lead to failures. It’s essential to choose bearings that fit the specific operational needs of your machinery.

Cleaning and lubrication play vital roles in bearing performance. Dry or contaminated bearings struggle to function smoothly. Regular checks can prevent unexpected breakdowns. Some operators overlook these details, thinking they can save time or money. This often leads to costly repairs down the line.

Understanding bearing specifications is not always enough. Factors like load, speed, and operating conditions matter greatly. Workers should be trained to recognize signs of wear. This knowledge helps in making informed decisions. Good bearings enhance overall machine performance, but neglect can lead to significant issues.

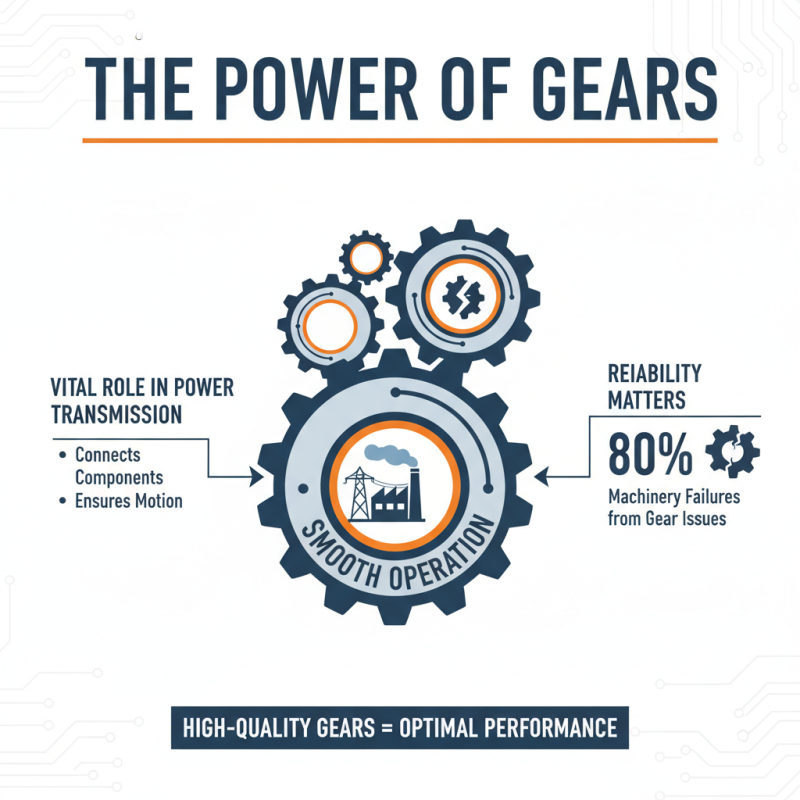

Importance of Gears for Efficient Power Transmission

Gears play a vital role in power transmission across various machinery. They connect different components to ensure smooth operation. According to a recent industry report, up to 80% of machinery failures can be linked to gear issues. This highlights the need for high-quality gears to maintain performance.

Efficient power transmission relies on the gear's design and material. Steel gears are known for their durability, while plastic gears are lighter and quieter. However, plastic gears may wear down faster under heavy loads. Regular maintenance practices can help prolong gear life and enhance efficiency.

Not all gears are created equal. The mismatch in gear sizing can lead to significant performance loss. A study found that improper gear alignment may reduce efficiency by over 10%. Understanding these nuances is essential for optimizing machine performance. Even small changes can yield major benefits in terms of output and longevity.

The Function and Types of Motors in Machines

Motors play a crucial role in machines. They convert electrical energy into mechanical motion. This conversion is fundamental for various applications, from simple fans to complex robotic systems. Understanding different motor types can enhance overall performance.

There are several kinds of motors commonly used in machines. AC motors are popular for their efficiency and durability in industrial settings. DC motors, on the other hand, are often utilized in portable tools due to their ease of control. Stepper motors offer precise positioning, making them ideal for 3D printers. However, each motor type has its limitations. AC motors may struggle with variable speed applications, while DC motors can have a shorter lifespan.

It's essential to choose the right motor for specific needs. An incorrect choice can lead to inefficiencies. For instance, using an AC motor in a setting requiring speed control could be problematic. Reflecting on motor selection can help avoid performance pitfalls and ensure that machines operate at peak efficiency.

Selecting the Right Controller for Optimal Operation

Choosing the right controller is critical for machine performance. It can be a challenging task. Various options are available, and each caters to different needs. Among the key factors to consider is compatibility with machine parts. A controller must effectively communicate with sensors and other components. If not, inefficiencies may occur.

Another important aspect is ease of use. A complicated controller can lead to errors. Operators might struggle to make adjustments in real-time. This can affect production output and quality. Practical training sessions can help. However, even new controllers can have unexpected quirks that require adjustments.

Finally, the cost is always a concern. Spending too much on advanced features may not always yield better performance. Striking a balance between cost and capabilities is vital. The goal is to find a reliable controller without overspending. Reflecting on these considerations will help in making the right choice.

Related Posts

-

How to Choose the Right Machine and Parts for Your Industrial Needs

-

2025 How to Choose the Right Knitting Machine Parts for Your Projects

-

Top 10 Tips for Buying Cheap Knitting Machines That Save You Money

-

2025 Top Insights: Machine Parts Trends Driving 10% Industry Growth

-

How to Choose the Best Knitting Machine for Home Use in 2025

-

Top 10 Essential Knitting Machine Parts You Need to Know About