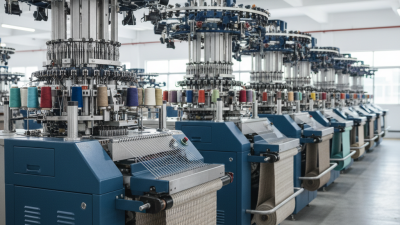

Top 10 Jersey Knitting Machines for Efficient and Quality Production

In the world of textile production, the efficiency and quality of manufacturing processes are paramount, and the jersey knitting machine stands out as an essential tool for achieving these goals. As industry expert Dr. Emily Carter once stated, "The right jersey knitting machine can not only enhance productivity but also significantly improve the final product's quality." This holds particularly true as manufacturers strive to meet the ever-evolving demands of fashion and functionality in knitwear.

In recent years, advancements in technology have revolutionized the jersey knitting machine market, making it crucial for producers to stay updated on the latest options available. With increasing competition, companies are exploring innovative machines that not only provide faster output but also maintain the integrity and softness of the fabric. This exploration has led us to compile a list of the top 10 jersey knitting machines that promise efficient and quality production.

The rise in demand for jersey fabrics across various applications—from athletic wear to everyday clothing—fuels the need for high-performance machinery. As we delve into the characteristics and advantages of these knitting machines, it will become apparent why selecting the right equipment is a game-changer for producers aiming to lead in the competitive textile landscape.

Overview of Jersey Knitting Machines and Their Importance

Jersey knitting machines play a vital role in the textile industry, enabling high-quality and efficient production of knitted fabrics. These machines are specifically designed for weaving jersey fabric, which is known for its stretchiness and comfort, making it a popular choice for clothing such as t-shirts, leggings, and sportswear. With advancements in technology, modern jersey knitting machines offer features that enhance their usability, precision, and output, thus meeting the growing demands of the fashion and apparel market.

Tip: Regular maintenance of your jersey knitting machine is crucial to ensure consistent performance. Schedule periodic check-ups and keep the machine clean to avoid any disruptions in production. Also, training your operators on the machine's functionalities can minimize errors and improve output quality.

Moreover, understanding the types of yarns used in jersey production is crucial. Different yarn characteristics can impact the final product's feel and durability. Experimenting with various fiber blends can lead to innovative fabric creations that capture consumer interest.

Tip: Always keep up with industry trends and innovations in knitting technology to stay competitive. Attending workshops and expos can provide insights on the latest advancements and help in making informed decisions about upgrading your machine or processes.

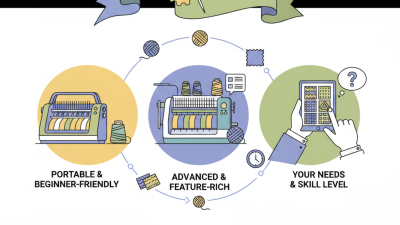

Key Features to Consider When Choosing a Jersey Knitting Machine

When selecting a jersey knitting machine, several key features play a critical role in ensuring efficient and high-quality production. One of the primary considerations is the machine's gauge, which refers to the number of needles per inch. According to the International Textile Manufacturers Federation (ITMF), machines with a finer gauge typically produce smoother fabrics with a higher quality finish, making them ideal for premium jersey applications. A gauge range of 28 to 36 is commonly preferred for lightweight jerseys, while heavier fabrics benefit from a coarser gauge.

Another important aspect to consider is the machine's knitting technology. The prevalent methods include circular and flat knitting, each offering distinct advantages. Circular knitting machines are known for their high-speed operation and ability to produce seamless tubes of fabric, making them particularly suitable for mass production. In contrast, flat knitting machines provide superior control and flexibility for intricate patterns and textures, catering to niche markets. Recent studies by the Knitting Industry Association indicate that manufacturers prioritizing flexibility in their machinery see a 20% increase in overall throughput, highlighting the importance of selecting a machine that aligns with production goals.

Additionally, automation features are becoming increasingly vital in modern jersey knitting machines. Automated yarn changers, tension systems, and real-time monitoring not only enhance productivity but also ensure consistent quality across batches. A report from the Textile Machinery Division indicates that automated systems can reduce downtime by up to 30%, thus leading to significant cost savings and improved turnaround times. Investing in machines equipped with these advanced features can provide a competitive edge in the fast-paced textile market.

Top 10 Jersey Knitting Machines: A Comparative Analysis

When selecting a jersey knitting machine, key factors such as efficiency, quality, and versatility are paramount. This comparative analysis delves into the top contenders in the market, highlighting their unique features and operational capabilities. Each machine is evaluated based on the fabric quality it produces, the speed at which it operates, and its adaptability to various jersey fabric types. This ensures that manufacturers can find a suitable option that meets their specific production needs.

Additionally, the ease of use and maintenance of these machines plays a critical role in their overall efficiency. Machines equipped with user-friendly interfaces tend to enhance productivity by allowing operators to quickly adapt to different settings. Furthermore, a machine that requires minimal downtime for upkeep not only helps maintain the flow of production but also contributes to long-term cost savings. By carefully analyzing these elements, manufacturers can make informed decisions, ensuring they invest in a knitting machine that will deliver both quality and efficiency in their production processes.

Efficiency and Quality: How Jersey Machines Impact Production

Jersey knitting machines play a crucial role in enhancing both efficiency and quality in textile production. These machines are engineered to deliver high-speed performance while ensuring that the fabric produced meets stringent quality standards. By utilizing advanced technology, automatic adjustments, and intricate designs, jersey knitting machines minimize downtime and waste, allowing manufacturers to achieve a higher output within shorter timeframes. This efficiency greatly reduces labor costs and accelerates the time-to-market for new products.

In terms of quality, modern jersey knitting machines are equipped with precision engineering that ensures consistent stitch density and fabric integrity. The evolution of knitting technology has enabled the production of finer, more complex patterns while maintaining the softness and stretchability characteristic of jersey fabric. Strings of data collected during the production process allow for real-time monitoring and adjustments, which not only enhances the quality of the final product but also ensures that every batch adheres to specific customer requirements. By investing in high-quality knitting machines, companies can meet the evolving demands of the fashion industry and boost customer satisfaction through superior products.

Top 10 Jersey Knitting Machines for Efficient and Quality Production

| Model | Gauge | Max Speed (RPM) | Needle Type | Power Consumption (kW) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 12 | 120 | Flat | 5.0 | 15000 |

| Model B | 14 | 110 | Cylinder | 4.5 | 12000 |

| Model C | 16 | 130 | Reg. Hook | 6.0 | 17000 |

| Model D | 10 | 140 | Spring | 5.5 | 16000 |

| Model E | 8 | 150 | Lace | 4.0 | 11000 |

Maintenance and Care Tips for Jersey Knitting Machines

Proper maintenance and care of jersey knitting machines are essential to ensure their longevity and optimal performance. Regular cleaning is crucial, as dust and fibers can accumulate and affect the machine's efficiency. Operators should follow a routine schedule to remove lint from the mechanism and check for any buildup around the needle beds. Additionally, lubricating moving parts according to the manufacturer’s guidelines will minimize friction and wear, contributing to smoother operation.

Another vital aspect of maintenance is monitoring the machine’s tension settings. Ensuring consistent tension helps prevent issues like uneven stitching or fabric distortion. Regularly testing and adjusting these settings can save time and resources in the production process.

Finally, operators should conduct periodic inspections of the machine for any signs of wear or malfunction. Addressing minor issues promptly can prevent costly repairs and downtime, thereby maintaining the quality of production.

Related Posts

-

Top 10 Best Circular Rib Knitting Machines for Quality Production

-

10 Essential Tips for Choosing the Best Circular Rib Knitting Machine

-

How to Choose the Best Circular Rib Knitting Machine for Your Needs

-

How to Choose the Best Circular Jacquard Knitting Machine for Your Needs

-

10 Essential Tips for Choosing the Right Machine and Parts for Your Business

-

How to Choose the Best Knitting Machine for Home Use in 2025